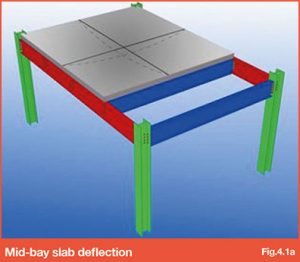

Deflection is defined as; the degree to which a structural element is displaced under load. All elements deflect so it is important to consider the magnitude of this deflection in a building system. The issue of deflection is more prominent when tight tolerances or deviations from datum are specified or required.

Construction Stage Deflection

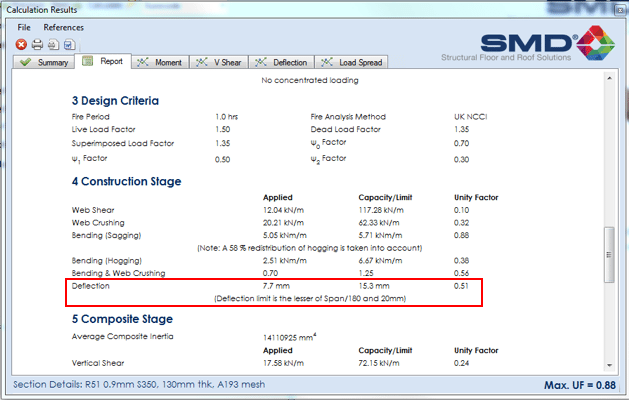

During the construction stage, the deck is considered to carry the load of its self-weight, reinforcement, wet concrete and construction loading (typically taken as 1.5kN/m²). The mid-span deflection limit for the deck is the lesser of span/180 and 20mm when ponding is not considered in the design. This is increased to the lesser of span/130 and 30mm when ponding is considered.

Frame deflection

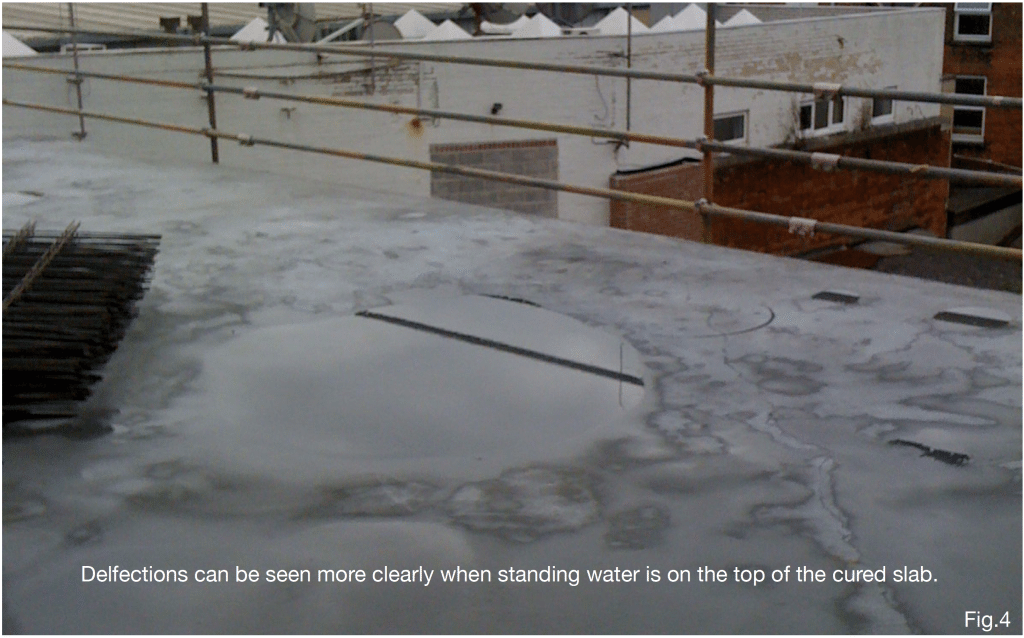

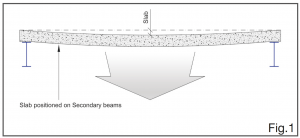

The total deviation from datum of the underside of a composite deck slab is dependant on the deflection of; primary beams, secondary beams and deck. The sum of these combined could result in deflections in excess of 40mm which means it is not practical to specify tight flatness tolerances.

It is noted in the Concrete Society TR75 that suspended composite deck slabs should be poured to a constant thickness and not to a datum. This ensures that deflections do not increase exponentially and avoids the risk of deck failures from overloading.

SMD Elements™ can be used to design and give an indication of the expected deflection of the deck during the construction stage (from concrete & construction loads).

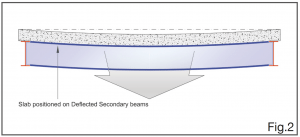

Ponding

It is necessary to limit the deflection at construction stage to minimise the volume of concrete placed on the deck. Excess deflection will lead to “ponding” of the concrete, which will increase the dead load applied to the structure.

Deflection limits for the composite deck are given in BS EN 1994-1-1 and BS5950-4. According to BS EN 1994-1-1, if the maximum deflection of the sheet is greater than 1/10 of the slab thickness, then ponding should be allowed for.

If ponding is considered, the additional weight of concrete will be shown in Section 2.3 of the SMD Elements™ report, see below.

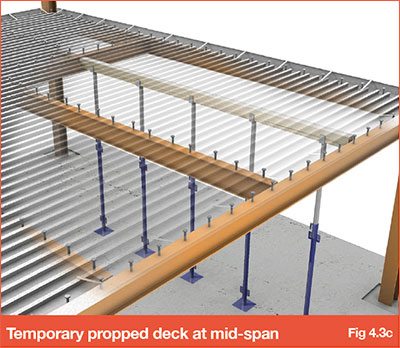

Propped Construction

If a tight tolerance is required, it may be advisable to prop the structure to limit deflection during construction.

In propped construction, the deflection that occurs after removal of the props must be considered. These deflections will be greater the earlier the props are removed (caused by the lower stiffness of the “immature” concrete). It is advisable that props are not removed until the concrete has achieved its design strength which should be verified by cube testing.

Composite Stage Deflection

The composite stage is when the concrete has cured and the deck is acting as tensile reinforcement. Deflections at this stage are calculated using elastic analysis, neglecting effects of shrinkage and by using the average cracked and uncracked second moment of area of the slab. This method is used in both British Standard (BS5950-4) and Eurocode (BS EN 1994-1-1) although the modular ratio calculation method varies between the two.

In the composite stage, the total deflection under Imposed Loads should not exceed the lesser of span/250 or 20mm.

Where brittle ceiling or floor finishes are required, it is critical to consider long term composite stage deflection of the slab.

7668 – St Osmunds School, Dorchester

Summary

- Deflection can never be eliminated, only controlled and minimised

- Cumulative deflection of the supporting structure and deck must be considered

- Consider propping and/or frame design if tight tolerances are required

- Suspended composite deck slabs should be poured to a constant thickness

- Temporary props should be left in place as late as practicable to ensure slab achieves design strength

TGN Online

For more information on this topic, see TGN Online Sections ‘s 4.1 specifically relating to this topic

Refer to our Best Practice Data sheet below.

DATA.10 – Deflections explained

Do you have a technical query?

Send your queries to our Technical Team

For Technical CPD’s, register your details for a presentation on this topic