The importance of early design communication for pre-studded beams

The shear stud provides an important function transferring forces between the beam and concrete slab. This is an important consideration when pre-welding studs and installing deck to pre-studded beams and one that can sometimes be overlooked.

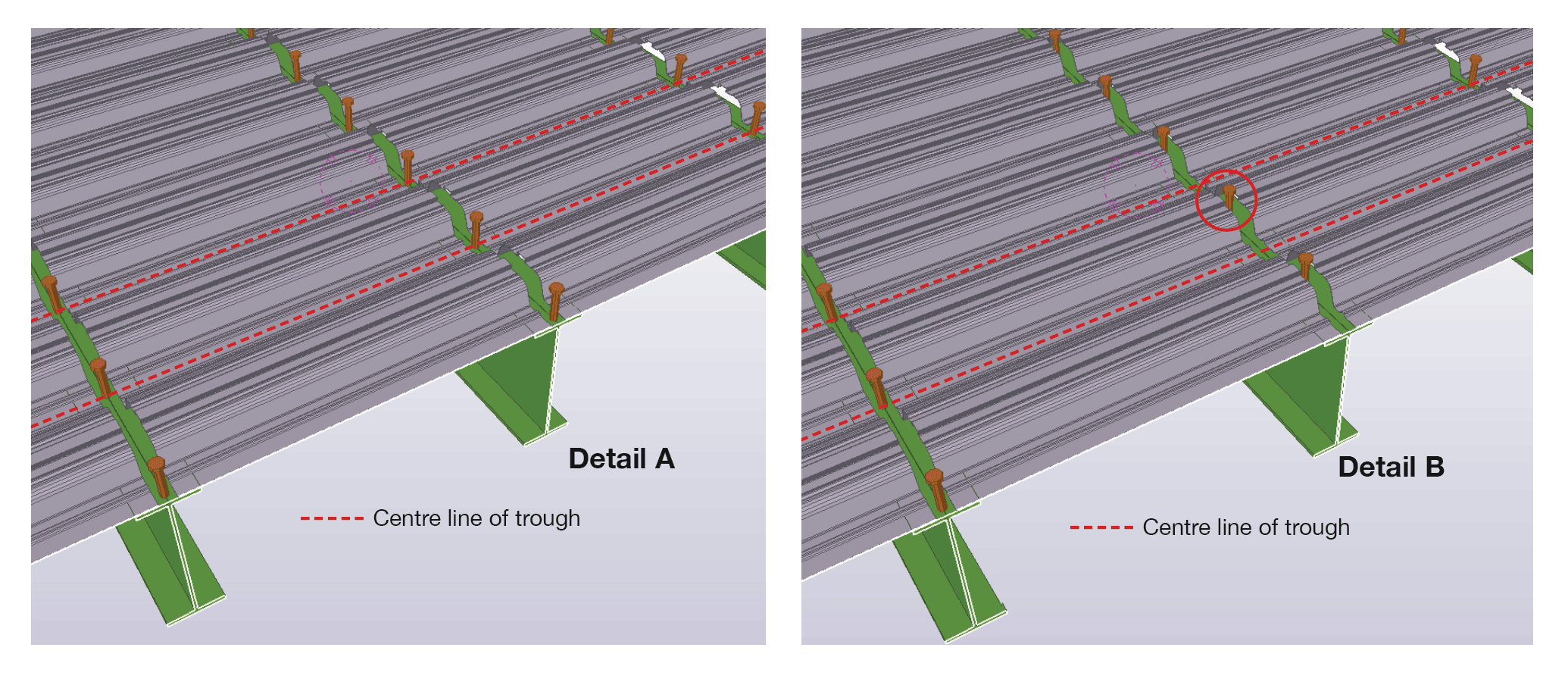

Composite beam design relies on a sufficient volume of solid concrete around each shear stud. When the deck is running at right angles to the beam centreline the stud should be positioned within the trough of the deck. When studs are being welded through the deck this is always the case, as it’s not possible to weld through the rib of the profile (shown in detail A). However, when beams are pre-studded it is important to ensure the deck troughs line through with the studs. To ensure this does not cause problems later in the build, early collaboration between the steel contractor (who typically welds the studs in the factory) and the steel deck contractor (who details the deck set-out) is essential in order to ensure that the studs are factory-welded in the correct positions. The studs must be welded to suit the deck set-out) configuration detailed by the deck contractor to ensure the deck troughs will line with the stud positions on the erected steelwork.

Failure to do this can result in studs not lining through with the troughs (as shown circled in detail B) which will lead to either a revisit of the beam design required or expensive remedial works to rectify the issue to ensure the beam meets the intended design requirements for the shear studs.

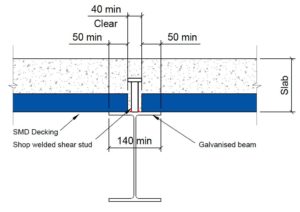

This issue is particularly important where beam flanges are less than 250mm, as with wider flanges it is possible to achieve the 50mm deck bearing on either side of the beam whilst maintaining adequate concrete around the stud. However, it is not uncommon to have pre-studded beams considerably narrower than this – see detail (below) showing the minimum practical limitation on pre-studded beams (140mm) to enable weld, stud, deck bearing and tolerance for stud position.

TGN Online

Register your details to gain access to our Technical Guidance Notes (TGN) Wiki pages. Alternatively, complete the form below and we’ll send you a hard copy of our TGN Manual.