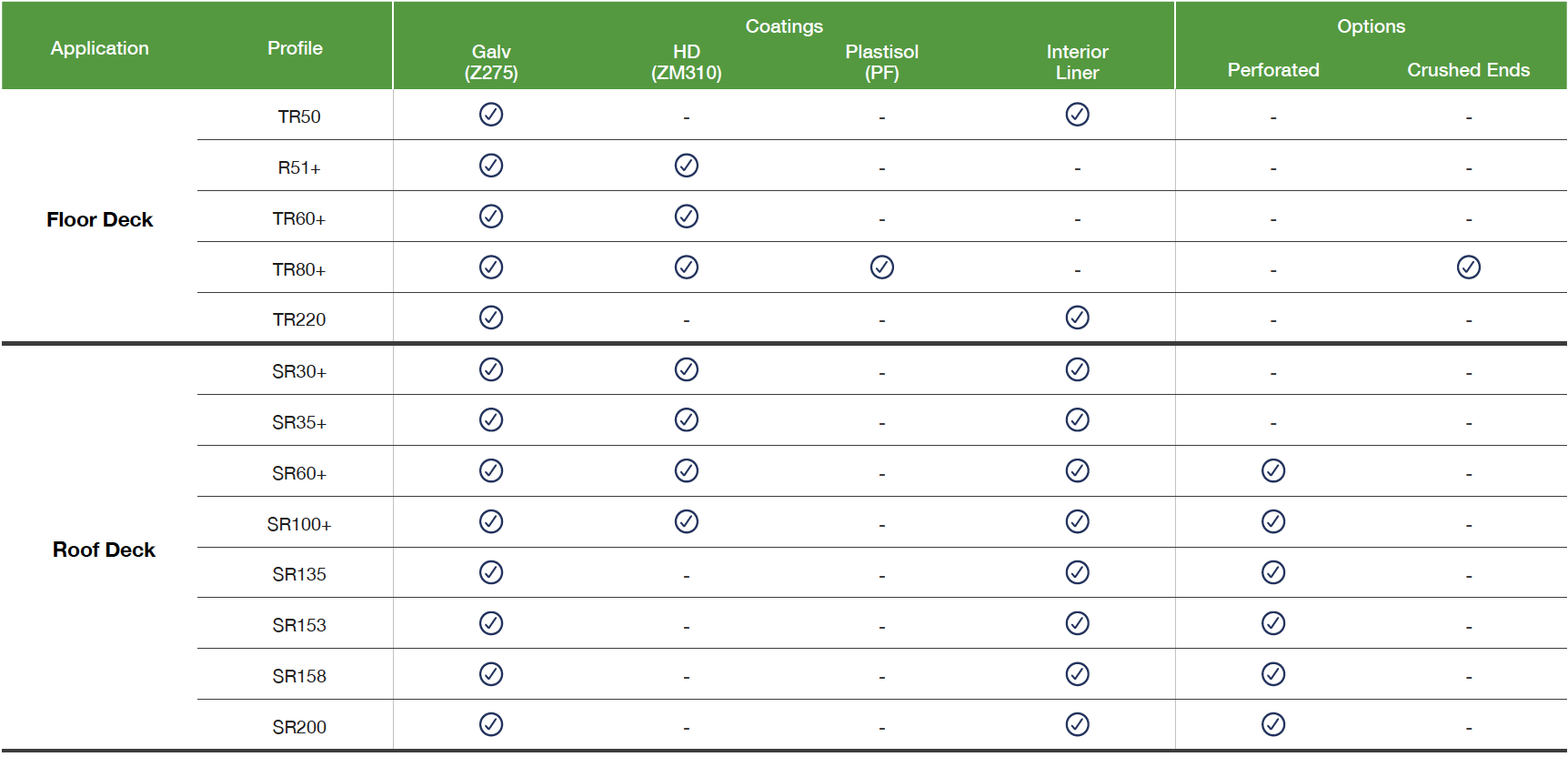

Coatings and Options

Product Features

All SMD decks are manufactured from steel coil in accordance with BS EN 10143 and BS EN 10346.

The environment in which the material will be located must be carefully assessed to determine which option is most suitable for your project.

Should our standard coating not meet the requirements of your project, we have developed a number of enhanced coating options to provide higher durability, reflectivity and aesthetic appearance where required.

Benefits

- Various coatings to suit all environments

- Colour options available

- Car park options by incorporating enhanced coatings and crushed ends

- Extend the life to first maintenance

- Installation benefits with crushed end deck

- Improved acoustic performance of roof decks

Standard Galvanised

SMD floor deck profiles are manufactured from steel strip in compliance with BS EN 10143 & BS EN 10346. Products are available in minimum yield strengths from 250 (S250) to 450N/mm² (S450) with a typical minimum coating mass of 275g/m² (Z) coating (0.02mm per side) or 120g/m² (ZM) in accordance with BS EN 10326, depending on product selected.

High Durability (HD)

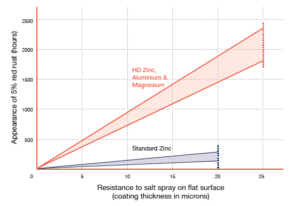

The HD coating is an enhanced metallic coating with a unique composition of zinc, aluminium and magnesium. It provides improved corrosion resistance with a similar coating thickness to the standard galvanised coating and excellent cut-edge protection (self healing effect). The enhanced metallic coating facilitates through deck welding making it the ideal choice for aggressive environments (e.g. chloride and highly alkaline) where composite beams and double span decks sheets are required.

Benefits using HD:

• Improved corrosion resistance with similar coating thickness

• Suitable for aggressive environments (e.g. chloride and highly alkaline)

• Excellent cut-edge protection (self healing effect)

Product specification

Coating weight – 310 g/m2 (total for both sides)

Coating thickness – 25μm per side

Structural steel grade – S350 (350 N/mm2)

The difference in coating

The dense and compact nature of the enhanced metallic coating used on the HD products provides superior corrosion resistance compared to the more porous structure provided by our standard hot dip galvanised Z275 coating.

Where could HD be used?

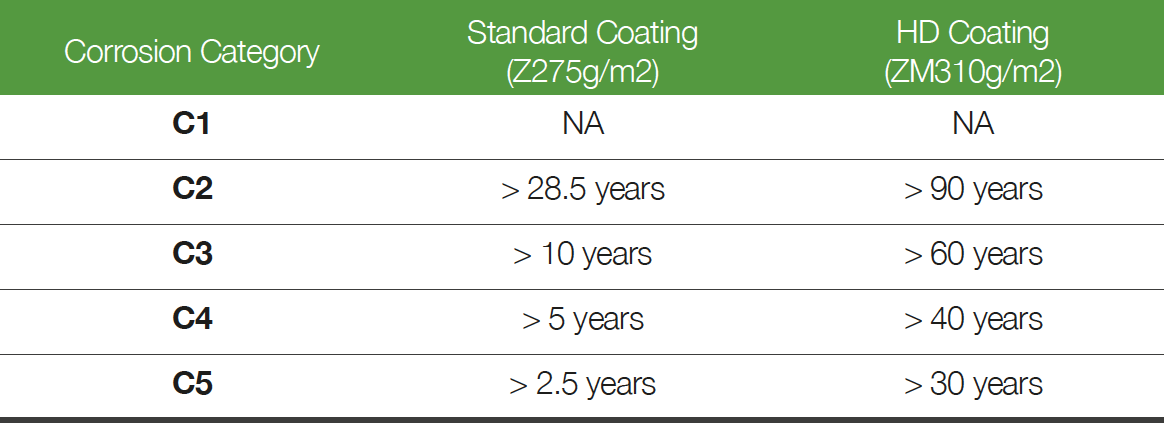

Due to the enhanced corrosion resistance provided by HD over that of the standard galvanised coating (shown in the table below), this enhanced coating should be considered in the following;

- External locations

- Car Parks

- Areas identified as aggressive environments (i.e. category C3 or above).

Corrosion behaviour – Salt spray test

These images and associated graph show comparison between the two coating options under salt spray test (highly chloride environment) carried out in the lab.

Thru’ deck stud welding with HD

• Suitability of stud welding tested in accordance with BS EN ISO 14555.

• Weld settings (WPS) for welding current, time, protrusion and lift available.

• Un-painted top flanges still required (as always).

Un-painted top flanges not suitable for the environment?

It might be worth considering pre-studded beams (painted) with single span deck sheets and crushed ends.

Interior Liner

The SR roof deck products provide aesthetically pleasing trapezoidal appearance, providing clean lines for situations where the soffit is exposed.

The aesthetic appearance and durability of the roof deck products can be enhanced by specifying an interior liner coating, the options available differ for shallow and deep roof decks as follows:

SR+ Shallow roof decks (up to 100mm deep) are available in ‘white interior liner coating’ with a 25 micron bright white polyester finish to the underside.

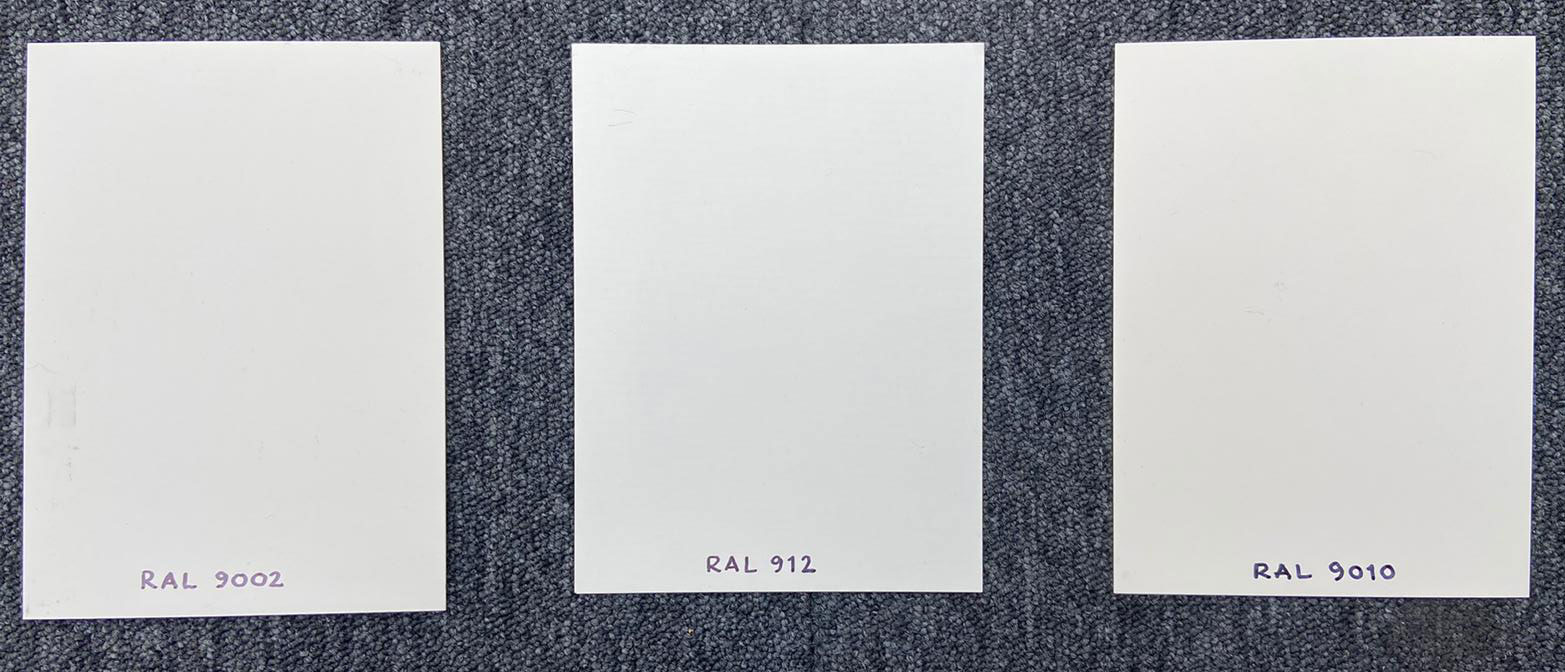

SR Deep roof decks (>100mm deep) are typically supplied with a 15 micron RAL 912 interior coating. RAL 912 is a colour developed to provide a single option suitable for use where RAL 9010 or RAL 9002 is required. As can be seen below, these three colour options are similar, hence RAL912 is the standard option available.

Other colours and soffit finishes are available upon request (including 25 micron thickness of RAL 9010), however these are likely to be subject to a premium charge, extended lead time and minimum order quantity.

Should your project have a specific requirement, contact the SMD team to discuss your requirement.

Crushed Ends (CE)

TR80+ floor deck sheets can be provided with crushed ends. This is the process of closing the end of the sheet ribs by ‘crushing’ the rib to form a slope to the end of the trapezoidal rib.

Where might it be used?

Crushed ends offer a number of benefits specific to certain types of construction or detail:

Quicker to install in single span situations as avoids need for end caps

Provides a greater concrete section locally to the shear stud, improving stud performance

Enables solid concrete strip over centre of support avoiding need for acoustic and/or fire profile fillers

Reduces grout loss on pre-studded projects where deck sheets have to be single span (refer to Fig.13.2b)

Popular in light gauge frame construction

As with all product options, crushed ends are not suitable in all situations as there are implications on sheet bundling and layout configurations.

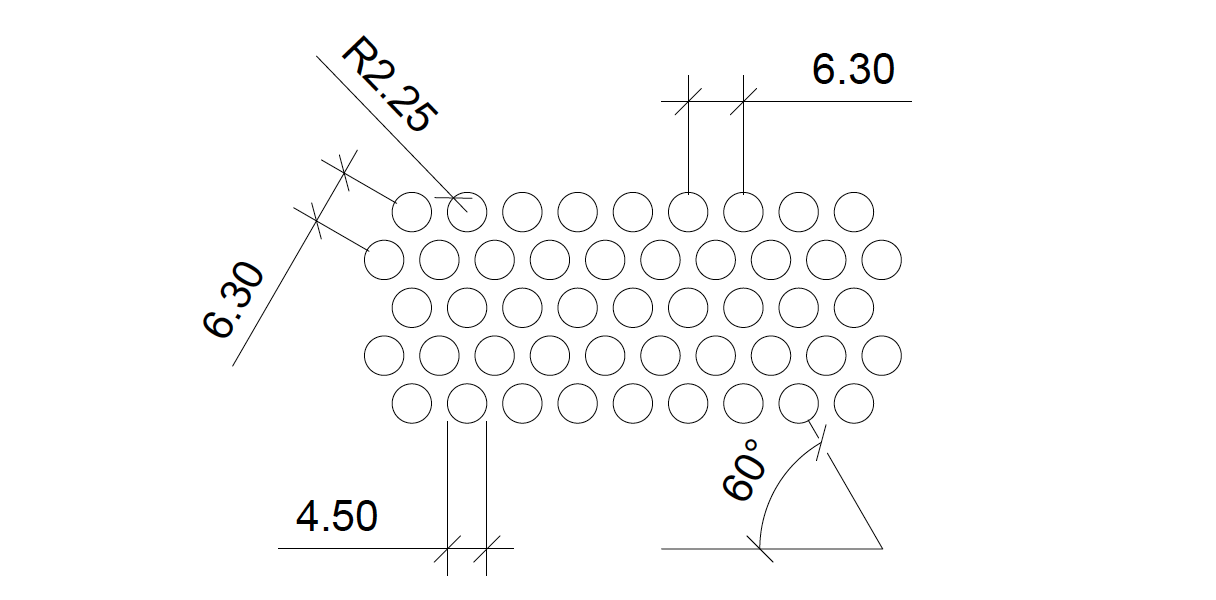

Perforations (P)

SR roof products can be provided with the webs partially perforated. When used with a layer of acoustic insulation as part of the site-assembled double skin system this provides sound absorption and reduces reverberation from noise within the internal space.

It is important to note that the inclusion of perforations within the profile affects the structural performance. Ensure the correct load/span tables are used when specifying perforated roof deck.

Pattern open area 46.0%.

Plastisol (PF)

Where composite floor deck is used in locations where the soffit is exposed, a durable colour coating is available.

This coating is only available the TR80+ profile due to the long-span capabilities of the product and the fact that studs cannot be welded through the Plastisol coating, therefore increasing the likelihood of single span decks if shear studs are required (pre-studded).

This coating provides improved durability and aesthetic appearance over the standard galvanised coating making it the preferred choice for exposed soffits where aesthetic appearance and light reflectivity is important, such as car parks.

Product specification

The PF coating is a 170 micron PVS Plastisol coating which can be used in almost any environment (both internal and external, inland or coastal) and is available with a warranty up to 30 years, subject to project location and specific application.

The PF coating should not be used where the composite design requires the application of through deck welded shear studs as it is not possible to achieve an acceptable weld due to the plastisol coating.

![Technical Guidance Sheet, High Durability Coating[72] composite beams](https://smdltd.co.uk/wp-content/uploads/2022/03/Technical-Guidance-Sheet-High-Durability-Coating72.jpg)