When it comes to pouring concrete onto metal decking, there is a lack of understanding of the difference between slab surface flatness and slab surface finish. These are two separate points that need addressing so they do not become an issue later in the construction phase for a client.

As outlined in BS 8204-2(1), MCRMA Technical Paper No.13/SCI Publication P300(2) and Concrete Society Technical Report 75(3) due to the deflections occurring in the metal decking and steel frame during the construction phase it is not possible to construct a suspended concrete floor slab on metal decking to a tight surface flatness designation or a defined datum level.

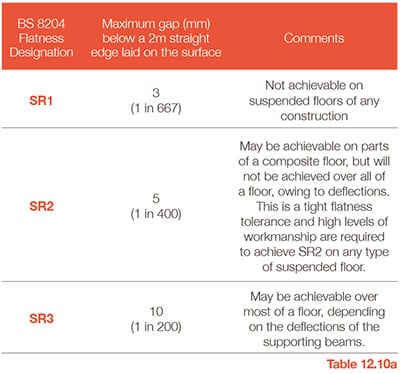

Table 12.10a (extract from SMD TGN Online and BS 8204) gives three tolerances for floor flatness.

The allowed deviation varies from 3 to 10mm depending on the flatness designation. However, as shown in Table 12.10a, SR1 is not achievable on metal decking suspended floors. To measure the surface regularity, the surveyor must place a 2m straightedge in direct contact with the concrete surface, resting under its own weight (below).

The straightedge must always be positioned parallel to the supporting beams and perpendicular to the metal decking span. The deviation will be measured using a slip gauge or graduated wedge from the underside of the straightedge, between two points which are in contact with the floor surface.

It should also be noted that the flatness and levels of the concrete slab post installation will change due to various factors. The concrete slab will deflect under loadings and there will be additional movement of the slab and steel beams, which will affect the flatness and levels of the concrete slab after construction. It is recommended that a survey of the floor should be taken within a month of installation, otherwise some of the above factors may have started to take affect and will invalidate the survey taken.

Surface finish

Surface finish is defined in BS EN 13670(4) and this Standard is adopted by NSCS 4th Edition(5) for concrete construction. There are four types of surface finish – Basic, Ordinary, Plain and Special. Whichever finish is specified, the concrete must be fully compacted to avoid cold joints, honeycombing and to minimise segregation, excessive blemishes or other defects in the hardened concrete. For unformed finishes it is important not to ‘over specify’ the quality of finish, particularly where it is covered up by following works.

Basic surface finish is applicable for areas receiving a levelling or wearing screed. The concrete shall be levelled by a skip float or similar process to produce a closed uniform finish. The image below shows an example of a ‘Basic’ finish from the SMD concrete team at the new 15,191m2Sainsbury’s complex in Selly Oak.

Float marks, localised ridges, surface laitance and a mottled effect will be evident in the final finish. There is also a risk of reinforcement ripple. This type of finish is suitable to most areas, but allowance should be given by a client for the appropriate surface preparation (removal of float marks, localised ridges, weak layer). A levelling screed or smoothing underlayment, in addition to appropriate surface preparation and possible use of a primer may also be required prior to the installation of thin sheet flooring.

‘Ordinary’ surface finish is applicable for areas to receive flooring materials, types of false floor or other raised finishes. The concrete shall be finished by floating or panning or similar process, to produce a level, uniform surface. The powerfloat finish will be free from ridges and provide a rough textured surface but float marks are to be expected.

Ordinary surface finish may be acceptable for the application of finishes such as tiles or carpet and is usually requested by roofing contractors for roofing finishes to pass ‘pull-off’ tests. It may not be suitable for thin vinyl flooring without grinding or an underlayment but the surface preparation may be less extensive than for a Basic finish.

‘Plain’ surface finish is applicable for areas without any other finish other than paint or surface coatings and maybe suitable for directly trafficked surfaces. The concrete shall be finished by trowelling, or a similar process, to produce a dense, smooth, level uniform surface. This is often erroneously referred to as a power-floated finish.

The image above is an example from our concrete team at the Sainsbury’s complex in Selly Oak where 3880m2 received a Plain surface finish for the back of house area. The back-of-house area was installed at a different time from the rest of the area as there was a requirement for two different types of surface finishes. From the image, you can see the difference from a Plain finish for the back of house area (left of picture) and the Basic finish for the rest of the floor (right of picture, step down area).

Due to the dense nature of a Plain surface finish, the surface may require abrading, typically shot blasting, to create a key to facilitate the application of subsequent finishes.

‘Special’ surface finish is applicable for areas requiring a specific texture, for example, tamped or brushed. To produce the concrete finish further working of a finish or other improvements as specified by the client will be required. Special must be defined in the project specification and will probably require approval of a benchmark area.

Responsibility

Most installations of concrete to metal decking should specify a surface flatness of SR3, which the Basic surface finish will achieve. This is primarily due to time, cost and the fact that follow-on trades will require additional surface preparation for the final floor finish. To achieve a surface flatness of SR2 then an Ordinary or Plain surface finish is required. To construct a suspended concrete floor onto metal decking it is not possible to achieve a surface flatness of SR1 and therefore neither surface finish used will improve this.

The concrete contractor has a responsibility to install the concrete as per the client’s specification and therefore should educate the client about surface finishes, flatness and deflections to mitigate any potential issues prior to commencing on site. This type of communication improves relationships with clients and will potentially increase revenue.

Straight edge survey

The video below demonstrates how to correctly undertake a straight edge survey to help understand how to effectively measure flatness on composite concrete slabs when using steel decking, also known as Surface Regularity over short distances.

[References]:

- BRITISH STANDARDS INSTITUTION, BS 8204-2. Screeds, bases and in situ floorings. Part 2 – Concrete wearing and surfaces. Code of practice. BSI, London, 2003+A2:2011.

- BRITISH STANDARDS INSTITUTION, BS EN 13670. Execution of concrete structures. BSI, London, 2009.

- RACKHAM, J.W., COUCHMAN, G.H. and HICKS, S.J. Composite Slabs and Beams Using Steel Decking: Best Practice for Design and Construction. MCRMA Technical Paper No.13/SCI Publication P300. MCRMA and SCI, 2009.

- CONCRETE SOCIETY. Composite concrete slabs using steel decking. Technical Report 75, Concrete Society, Camberley, 2016.

- CONSTRUCT. National Structural Concrete Specification for Building Construction. Fourth Edition, The Concrete Centre, Camberley, 2010.

Written by Will Corsie, SMD Concrete Construction Coordinator

TGN Online

For more information on this topic, see TGN Online Sections ‘s 12.9 and 12.10 specifically relating to this topic

Do you have a technical query?

Send your queries to our Technical Team

For Technical CPD’s, register your details for a presentation on this topic