Expected tolerances

It is important to understand the various surface finishes that can be achieved using metal decking, as these may differ to what you can expect to achieve using other types of construction. In addition to this, the tolerances expected are governed by more than just the deck itself.

Following a previous Monthly Technical Query (MTQ), Pouring Composite Slabs, this MTQ covers items of surface finishes and tolerances for composite decked slabs.

The concrete surface finish and flatness tolerance should be specified by the Project Engineer and agreed before commencement of any decking works. Finishes are specified as one of the following:

Surface Finish Types

Skip/Easy Float (Basic Classification)

Applicable for areas to receive a levelling or wearing screed. Float marks, localised ridges, surface laitance and a mottled effect will be evident in the final finish. There is also a risk of reinforcement ripple.

Pan/Combi (Ordinary Classification)

Applicable for areas to receive flooring materials, types of false floor or other raised finish. It may not be suitable for thin vinyl flooring without grinding or an underlayment. A Pan finish will exhibit ridges (although not to the degree of Basic methods), provide a rough textured surface and will vary in consistency in its final appearance.

A Combi finish will be free from ridges but float marks are to be expected.

Full Polish (Plain Classification)

Applicable for areas without any other finish other than paint or surface coatings, and provides a uniform dense smooth surface typically produced by power-trowelling. This may be suitable for directly trafficked surfaces. Due to its dense nature, a Plain finish may need abrading (typically, shot blast) to create a key to facilitate the application of subsequent finishes.

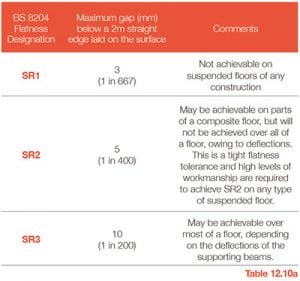

Flatness is defined in BS EN 8204-2 as local deviation under a straight edge. The permitted deviations are summarised in the table below:

For slabs poured onto metal decking: a SR3 flatness tolerance is achievable when using a skip float finish increasing to SR2 with a power-float finish.

There are many factors affecting tolerances of composite slabs:

- Methods of levelling the concrete

- Deflection of the steel decking and frame

- Method of finishing the surface

- Experience of the concrete team

Industry experience has shown that there is a high chance of crazing, the irregular polygon patter of fine cracks in the surface, when a trowelled finish is used. This should not be considered a defect and it generally has no adverse effects on the performance of the slab.

On completion of any project where SMD has undertaken the concrete works, SMD will carry out a straightedge survey in accordance with SCI P300 and issue this to their client to evidence compliance with the specification.

The straightedge must always be taken between two points of contact, parallel to the supporting beams, i.e.- perpendicular to the decking span.

For any queries regarding surface flatness and tolerances, please contact our Concrete Team.

For more information on this topic, see TGN Section 12.10 specifically relating to this topic

TGN Online

For In-depth Technical Guidance Notes on a range of topics, refer to TGN Online

Do you have a technical query?

Send your queries to our Technical Team

For Technical CPD’s, register your details for a presentation on this topic