Its been over 15 years since SMD partnered with ArcelorMittal Wire Solutions to develop and test the TAB-Deck® steel fibre reinforced composite slab solution in conjunction with SCI.

Although traditional steel mesh reinforcement remains the popular choice of the industry, we have seen a growth in the interest and use of TAB-Deck® in the past year, with more people understanding the differences from traditional reinforcement and the benefits it brings from both a construction and environmental point of view. Some of the differences and benefits are discussed in more depth here.

Benefits aren’t always obvious

When it was first developed, the benefits of TAB-Deck® appeared obvious:

- Reduction in man power with little or no mesh fixing

- Shorter programme times

- Reduced lifting and manual handling operations for mesh/bar

- Removal of trip hazard

Companies that understand these and don’t just focus on material cost alone, are now seeing the added benefits which perhaps were not so obvious when the system was first developed. With the climate emergency very much on everyone’s lips, more recently we have seen steel fibre reinforcement being considered in situations where it reduces the amount of steel as a raw material, and as a result embodied carbon, compared to traditional mesh/rebar reinforcement. In the past arguments like this may have been pushed aside due to the blind focus on cost that often exists in the construction industry. However, with the price and availability pressures of mesh reinforcement in recent months it’s now possible to backup those environmental decisions commercially, which has got to be a change for the better.

Design specifically for fibres rather than chop & change

Whilst TAB-Deck® has many benefits, it is not right for all projects! It is much more efficient in terms of design to design for steel fibres from the outset, rather than trying to change mesh to fibres late in the day. This is due to a number of key design recommendations that we at SMD have developed in the last 15+ years’ experience of steel fibre concrete being poured on upper floor decks.

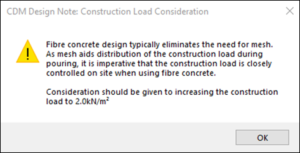

- Increase construction imposed load – Without mesh to spread the foot traffic during concreting, we recommend increasing the construction load to 2kN/m². Whilst this is beyond the design standard, those standards have rules based on mesh reinforcement, and experience has shown that deflections can be excessive when deck is designed to the limit with only a 1.5kN/m² construction imposed load.

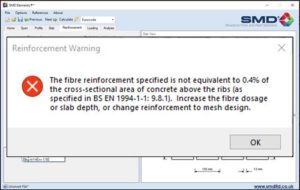

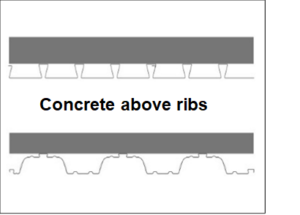

- Check the moment resistance of the slab above the ribs – In a traditional mesh reinforced slab, the mesh is consistent in all areas of the slab. However, with a steel fibre reinforced slab the resistance to cracking differs in the shallower parts of the slab above the ribs. Therefore, we recommend checking the moment resistance of the fibre reinforced slab section above the ribs and then converting this into an equivalent mesh area to then check this against the minimum reinforcement percentages in the design standard – this is already implemented as part of SMD Elements® design checks.

- Concrete mix design – This is critical to ensure effective distribution and workability for the fibre reinforced concrete.

More insight.

Hopefully this article has given you some insight to the TAB-Deck® system? If you are interested in learning more, you can find extensive guidance and information including the influence on Composite beam design in our steel fibre reinforced concrete design guide or through contact with our steel fibre partner ArcelorMittal Wire Solutions – 0114 239 2601.

TGN Online

Register your details to gain access to our Technical Guidance Notes (TGN) Wiki pages. Alternatively, complete the form below and we’ll send you a hard copy of our TGN Manual.