11.3 - Unpainted top flanges

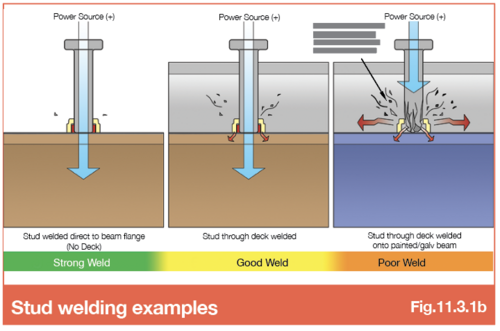

Where beams are to receive thru-deck welded shear studs, the top flanges are to be free from any type of paint, grease, loose rust or any other coating, as this prevents effective welding and will subsequently reduce the final weld strength.

Studs welded straight to beam (not through deck)

Excellent connection between the stud and bare steel with minor splatter. Weld concentrated inside the ferrule cavity (refer Fig.11.3.1b).

Paint-free top flange

Generally good connection between the stud and bare steel with minor splatter. Weld generally concentrated inside the ferrule cavity. Studs tested (5%) to check for weld quality.

Through-deck welded studs to a paint-free top flange beam, this will cause occasional weld contamination due to galvanised sheet but generally good connection (refer Fig.11.3.1b).

Important Note: When masking the top flange before painting, the full top flange should be masked. Where a return of paint at the toes of the beam flange is required, this should extend no more than 15mm from the beam toe

11.3.1 Stud welding contaminated beams

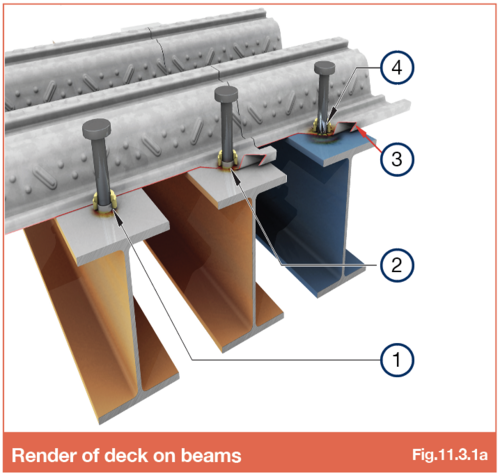

Fig.11.3.1a represents three examples of studs being applied to beams:-

1. Stud applied direct to top flange of paint-free beam

2. Through-deck welded shear stud on un-painted beam

3. Deck rendered cut back for clarity

4. Stud welded on a painted top flange

Painted top flange

Poor/no connection between stud and beam (refer right example in Fig.11.3.1b) due to paint application, weld cannot be concentrated into a localised area inside the ferrule resulting in an erratic weld patter and failure of stud.

Poor weld between the stud and beam illustrated. Painted or galvanised beam contaminates parent material of weld site to the point that weld material is exploded from base of stud leaving very little weld intact.

Refer to BCSA Code of Practice for Metal Decking and Stud Welding Publication No. 37/04 for more information

Go to NEXT section