11.5 - Static generator or mains supply

In many instances, due to the low environmental impact, the preferable option is a 415 volt 3-phase (125 amp per phase, with a HRC fuse or Class D, or above, circuit breaker) mains supply.

For large city centre contracts where mains supply is unavailable and access is restricted for a mobile rig, static generators approximately 3.0m long, 2.0m wide and 2.0m high weighing 6 tonnes can be provided as an alternative. Where a static generator is required, it should be positioned in a well ventilated area and consideration should be given by the Structural Engineer to its location to avoid overloading of the steel frame.

11.5.1 Power Supply for Stud Welding

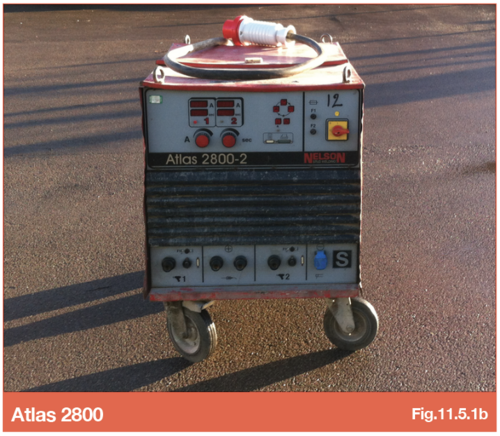

This covers the mains power supply required for the Nelweld 6000 series & Atlas 2800 series rectifiers.

Specification

Voltage 415 @ 50Hz

Socket type 125-6h (5 Pin, 3 Phase + N + E + Pilot)

Amperage 125 amps per phase

Protection HRC fuse preferred, if using circuit breaker Class D or better

Typical load during weld cycle 350 to 400 amps per phase on the incoming for 1.5 seconds.

Inrush current up to 1300 amps for 1 to 2 cycles

Implementation

Fig.11.5.1c indicates the type of plug and socket that is required to connect stud welding rectifiers to a site mains supply. All rectifiers supplied by SMD will be fitted with this type of plug. Sites must terminate the mains supply at a compatible socket. Should power be supplied by a generator, it must not be supplying power to other plant as it may overload the generator capacity.

Mains outlets need to be available at every other floor level. Studs can be installed to a 60m radius from the outlet location. For floors in excess of 1500m² more than one power point may be required.

SMD do not use these plugs and sockets when using a static generator. When a generator is utilised (min 250kva) for the power supply the rectifier must be hard wired into it (by others).

Go to NEXT section