11.8 - Minimising grout loss

Deck sheets are designed to butt join with the ribs of the profile lined through to avoid gaps and minimise grout loss.

Metal deck is not intended to provide a watertight solution, therefore small quantities of grout and water loss are inevitable. Gaps in excess of 5mm should be sealed using either tape or expanding foam. Generally, gaps less than 5mm are acceptable with no special provision as they are too small to allow aggregate to escape, although grout loss will occur.

If the soffit and trim is intended to be fully exposed in its final condition, consideration should be give at tender stage to the taping of all joints prior to concreting or alternatively jet-washing the underside of steelwork post concrete pour.

The use of needle head vibrating pokers is not recommended as these can encourage greater grout loss.

11.8.1 Seepage and Concrete Overspill

Issues with concrete grout loss/seepage and overspill is commonplace when concreting on steel decking.

It is important to understand that steel decking is not designed or intended to provide a fully tanked solution. Therefore, it is inevitable for some grout loss/seepage to occur through the deck and overspill at perimeter edges when placing concrete to steel decking or squeegeeing away excess bleed water from surfaces prior to, and during power floating operations (Fig.11.8.1a and 11.8.1b).

This occurrence is not detrimental to the structural integrity of a composite slab.

The degree of seepage/loss/overspill can vary and Project Teams should consider what effect this may have on the soffit of the deck, perimeter edge trim outer faces, supporting steelwork and floors below, particularly when architectural finishes are specified pre or post concrete installation or when they are to remain fully exposed in their final condition.

In accordance with BCSA code of practice, all gaps in the steel decking which are greater than 5mm in width should be sealed by the decking contractor as standard practice, using either tape or expanding foam.

Further preventative measures can be considered to minimise seepage/loss/overspill during concrete placement (e.g. additional taping or foaming of all joints or by the use of additional fixings). It is however, essential to recognise that these additional measures will not guarantee a seepage/loss/overspill free structure due to deflection of the steel decking, along with the supporting frame during concrete placement making it unfeasible to seal joints effectively.

Due to most concreting works taking place in an exposed environment, excess rain water on the decking will be forced out through gaps in the decking/flashing/steel when concrete is placed. Protection to exposed steelwork at working level can be achieved with the use of light gauge polythene wrapped around columns/cross braces etc. This will prevent issues caused by splashes from pouring concrete and subsequent finishing through power floating at the working level only.

Proceeding with concrete pours in wet weather can exaggerate concrete grout loss/seepage at column locations and overspill at perimeter edges due to finishing processes.

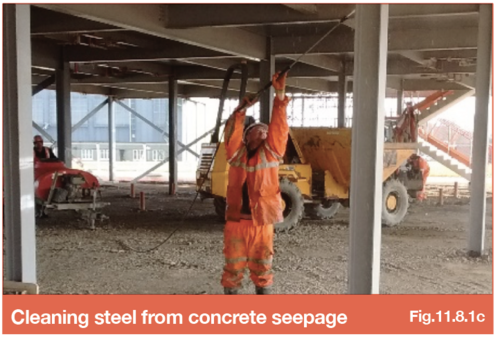

SMD recommend in areas where the soffit of the deck, perimeter edge trim outer faces, underside supporting steelwork (beams and/or columns) have been affected by concrete seepage/loss/overspill, manual pressure washing (Fig.11.8.1c & Fig.11.8.1d) is carried out to accessible areas the following day after concrete placement. This process however, will not guarantee that the finished steelwork will be free from residual seepage/staining on completion (Fig.11.8.1b).

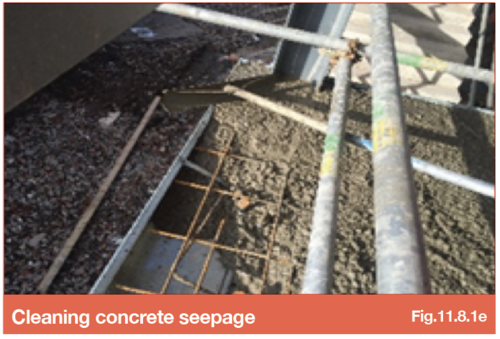

However, there are many factors that can prevent the feasibility of this operation such as restricted access to underside areas, obstructed access to perimeter edges by scaffolding (Fig.11.8.1e), toe-boards, easi-edge protection systems (or similar) (Fig.11.8.1f), height differences exceeding 3.5m between floor levels and the requirement for a water supply within 20m of working areas..

Go to NEXT section