13.1 - High Durability floor deck

What is HIGH DURABILITY HD?

Our HD products provide the same structural capacity as our standard floor deck range but come with an enhanced metallic coating with a unique composition of Zinc, Aluminium and Magnesium.

Benefits:

- Improved corrosion resistance with similar coating thickness

- Suitable for aggressive environments (e.g. chloride and highly alkaline)

- Excellent cut-edge protection (self healing effect)

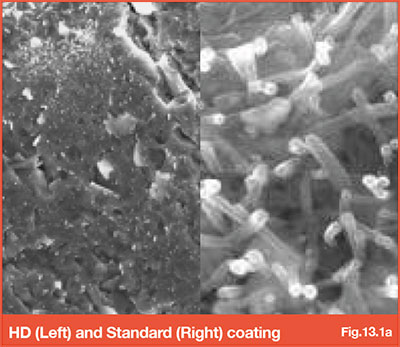

The difference in coating

The dense and compact nature of the enhanced metallic coating used on the HD products (refer Fig 13.1a (left image)) provides superior corrosion resistance compared to the more porous structure provided by our standard Hot Dip Galvanised Z275 coating (refer Fig 13.1a (right image)).

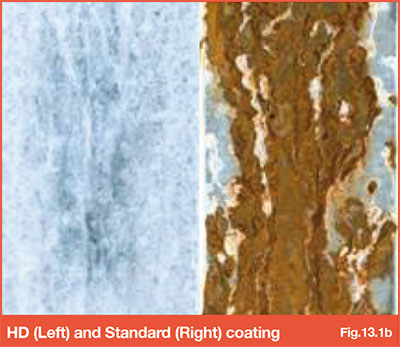

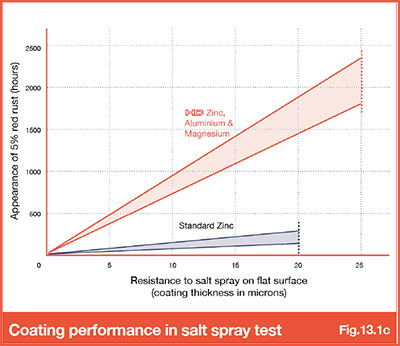

Corrosion behaviour - Salt spray test

The samples in Fig 13.1b and graph (refer Fig 13.1c) show comparison between the two coating options under salt spray test (highly chloride environment) carried out in the lab. Time scales for samples shown in Fig 13.1b are:

- HD after 34 weeks

- Standard Zinc after 6 weeks

Where could HD deck be used?

- External locations

- Car Parks

- Areas identified as aggressive environments (i.e. category C2-C3 or above)

HD Product Specification

- Coating weight - 310 g/m² (total for both sides)

- Coating thickness - 25μm per side

- Structural steel grade - S350 (350 N/mm²)

Composite beams

Thru-deck stud welding with HD:

- Suitability of stud welding tested in accordance with BS EN ISO 14555.

- Weld settings (WPS) for welding current, time, protrusion and lift available.

- Un-painted top flanges still required (as always).

Un-painted top flanges not suitable for the environment?

Consider pre-studded beams (painted) and single span deck sheets with crushed ends (refer to Section 13.2 - Crushed ends deck sheets).

Refer SMD Sheet 1023 High-Durability

Go to NEXT section