12.1 - Site considerations

Building envelope

To enable an acceptable surface finish to be achieved, where possible, concrete pours should be carried out in an enclosed environment to provide adequate protection of the works from prevailing weather conditions (including wind, surface water, frost, driving rain and excess heat from the sun). Ambient temperatures must be suitable for concrete placing and finishing operations. In some instances this may require provision of heaters and/or insulation material to the top and underside of the slab. It is appreciated that this is not always feasible due to site programme and logistics etc. A Project Team must also understand that the lack of a weatherproof building envelope could have a detrimental effect (dependent on severity of the conditions) on the final surface finish achievable and this is beyond the control of a flooring contractor.

Wash-out facility

Adequate wash-out facilities for the disposal of surplus concrete material from both the pump and trucks should be provided, i.e. designated area in the ground and/or polythene lined skips, including a water supply for cleaning of plant and equipment, refer Section 12.13 Surplus concrete waste for more information.

Lifting to level

A means (crane/telehandler) for lifting plant and materials to level is required to enable works to commence. Loading platforms Where loading out plant and materials directly to the working area is not possible, loading platform/s should be provided. These should be safe and adequately sized to permit the storage of plant, materials and enable site personnel to access from all sides.

Ground conditions

Suitable hard standing areas are required to accommodate all construction traffic loads associated with the concrete works, including concrete pump and trucks.

Concrete Pumps - Gross Vehicle Weight of 20 tonnes and have standard road suspension and tyres. Sufficient ground bearing pressure is required if plant is to safely access site, undertake required work & exit. Required positioning for the vehicle need to be pre agreed dependant on pour sequence and site layout.

A visual inspection is often adequate however, it is essential that the assessment is made by persons with relevant knowledge and experience to know when further expert advice and assessment is required.

Ground bearing capacity can also change throughout the project with weather & site conditions such as new excavations, a view of the conditions needs to be an on-going activity.

It is important to note if the ground conditions are unsuitable on our arrival to site, for Health and Safety reasons ours teams will not be able to carry out their works, which in turn could lead to additional delays and costs.

Weather review and potential effects of pouring concrete in an exposed environment

SMD aim to provide the best possible surface finish to a slab on all projects. To enable SMD to provide an acceptable surface finish, it is advisable for concrete pours to be carried out in an enclosed environment to provide adequate protection of the works against inclement weather. Whilst SMD appreciate that it is not always feasible for the client to provide a weather proof envelope due to site programme, it should be understood that this may have a detrimental effect on the final surface finish (depending on the severity of the conditions).

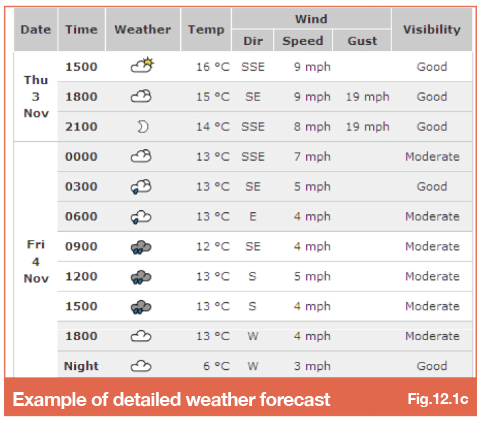

As part of our aim, we will always review the latest weather forecast information on The Met Office website 24 hours before a scheduled pour date. The forecast for the project location will be displayed similarly to the view illustrated in Fig.12.1c.

Should the forecast appear unfavourable, this will be highlighted to the client’s on site management team for their review accordingly. The ultimate decision as to whether to proceed with a concrete pour will always be that of SMD’s client. Should the decision to cancel and rearrange the pour be taken, this must be established by 12:00pm the day prior to the programmed pour date to avoid cancellation charges from the pump supplier, concrete plant and labour operatives.

SMD cannot be held responsible for weather damage incurred to concrete slabs where pours are carried out against the advice of the SMD project management team upon review of the most up to date weather forecast. In the event of cancellation, SMD will aim to reprogramme the pour at the earliest opportunity. It is unlikely (in most cases) to be rearranged for the following day as due notice of up to 1 week needs to be given in order to rearrange labour, plant and materials.

Cold weather has the potential to effect concrete operations on steel decking as steel decking is a poor insulator. Precautions to prevent the concrete at the steel interface falling below 5°C should be provided (by others) until the concrete has achieved a strength of at least 5N/mm². Additional preventative measures should also be considered (by others) for protection of newly laid concrete surfaces against the effects of frost.

Rain damage can have a varying impact on a slab (Fig.12.1d-f), from light cosmetic “pitting” on the surface to washing away some of the cement from the concrete and exposing the aggregate.

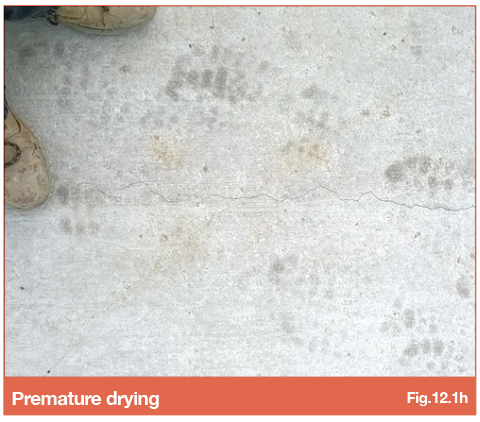

High/cross winds or sunlight may cause premature drying of the concrete surface leading to surface delamination and/or premature plastic shrinkage cracks occurring (Fig.12.1g-i). High winds will also impact the safe operation of the concrete pump, particularly on pours at height.

Access / egress facilities

Safe means of access and egress must be provided, positioned to suit the start and finish locations of each pour area. Specific consideration should be given to this item when powerfloat operations are to be carried out.

Site protection

Adequate protection from on-site activities must be provided to all adjoining properties/premises, including items contained within its boundaries. This is not specific to the concrete works and should typically be considered by a Main Contractor at planning stage. Where there are completed works in close proximity to the concrete pour area, adequate protection must also be provided to avoid damage.

Other trades

Adequate protection and/or segregation areas must be provided for other trades working in the vicinity of the concrete works.

Go to NEXT section