Difference between revisions of "5.6 - Forming service holes"

| Line 22: | Line 22: | ||

| − | [[File:5. | + | [[File:5.6c_table_(V10.3).png|400px|link=]] |

Revision as of 11:31, 20 November 2020

When it is necessary to form service holes in a composite slab the following general rules are recommended. For openings at right angles to the deck span:

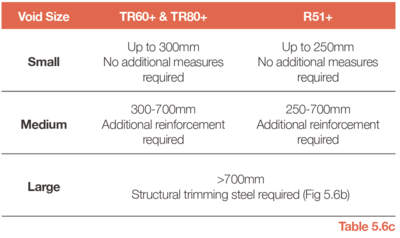

1. Up to 250mm (for R51+) or 300mm (for TR50, TR60+ and TR80+ profiles): Openings such as these require no special treatment (i.e. no additional reinforcement). Prior to placing of concrete the opening is boxed out. When the slab has cured, the deck is cut by others using a non-percussive tool. (Refer Fig 5.6a).

2. Greater than 250mm (for R51+) or 300mm (for TR50, TR60+ and TR80+ profiles), but less than 700mm:

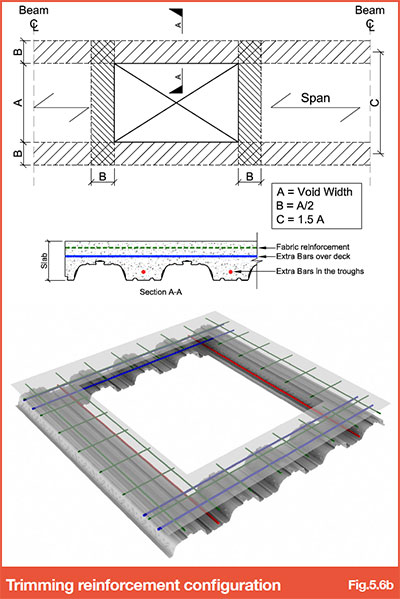

Additional reinforcement is required around the opening, generally designed in accordance with BS EN 1992-1-1 or BS8110. The forming of the hole is as item 1 (Refer Fig 5.6a and 5.6b).

3. Greater than 700mm: Structural trimming steelwork designed by others and supplied by the steelwork fabricator, is recommended.

Items 1 and 2 relate to holes in isolation and not to a series of holes transverse to the direction of span, which should be considered as one large void. In these cases, the metal decking should only be cut after the slab has cured. Typically, for a void to be considered in isolation, the clear dimension between void edges in a direction transverse to the deck span should be no less than the greater of 666mm or 1.5 x void width (A in Fig 5.6b), providing no excessive concentrated loads apply to the unsupported edges.

These are guidelines only and particular requirements should be checked by the project structural engineer. SMD’s responsibility excludes the design of any additional framing or slab reinforcement for holes or openings.

When forming holes in the decking, consideration needs to be given to Health & Safety. Due consideration should be given to protect against falling through holes. If possible, handrails should be erected around the void.

Alternatively, SMD can provide:

• A temporary cover to the opening, by decking over the void (unconcreted), for removal by others at a later date.

• VoidSafe™ Protection System - Refer Section 13.3 - VoidSafe™ Protection System

Refer to VoidSafe™ Protection System Brochure

Back to Contents Page

Need Further Guidance?

Contact us on +44 (0)1202 718 898 or email our Technical Team