7.4 - Durability

SMD Profiles – Standard Coating

Unless otherwise specified, SMD profiles are manufactured from hot-dip galvanised steel strip designated: BS EN 10346: S350GD+Z275-N-A-C (S450GD+Z275-N-A-C for 450N/mm² grade products)with a standard 275g/m² coating which equates to 0.02mm (20μm) per face.

Hot-Dip Galvanised Coating

Although the galvanising provides a protective coating, it does weather, albeit at approximately one tenth of the rate of steel (depending upon the prevailing conditions and thickness of coating).

Factors which may affect the speed at which the galvanising deteriorates and subsequently exposes the steel substrate to produce rust as a result include:

- Length of time the installed deck is exposed to the elements before the building envelope is complete

- Localised damage to the deck during installation (deck sheets are typically dragged across the supporting structure which could scuff the finish and remove some of the coating)

- Failure to provide adequate ventilation when allowing buildings to dry out leading to condensation on the deck soffit

- High humidity levels/poor ventilation when the building is in use

- Presence of chemical agents

- Presence of other liquid based materials that are detrimental to the zinc coating

- Airborne pollutants

NOTE – Both the 275g/m² and 310g/m² coatings options for SMD products are adequate for the relatively short period of exposure between rolling of the deck profile and enclosure within the building fabric.

Corrosivity Category

Useful references on the life to first maintenance (LTFM) of galvanised steel coil include:

- Galvanizers Association, “The Engineers and Architects Guide: Hot-dip Galvanizing”

- Corus Strip Products UK, “Protected with strength - Solutions in Galvatite hot-dip galvanised steel”

- The Steel Construction Institute, P262 - Durability of Light Steel Framing in Residential Building: Second Edition

- SCI Advisory Desk Note 247: Use of Composite Construction in an Aggressive Environment,” New Steel Construction, April 2010.

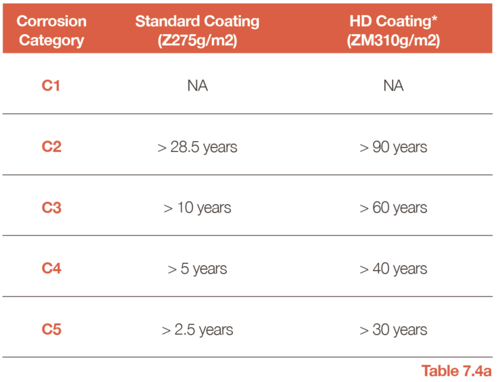

In summary, the above references conclude the LTFM for galvanised steel coil with a 20 μm coating as shown in Table 7.4a for the different corrosivity categories.

BS EN ISO 9223 documents corrosivity categories C1 to CX; with C1 for Interior: dry (low corrosivity) to CX Extreme Humidity (high corrosivity).

The Galvanizers Association (2011) and Galvanizers Association of Australia (2012) providing useful guidance on Corrosion Categories, Typical Environments and Corrosion Rates.

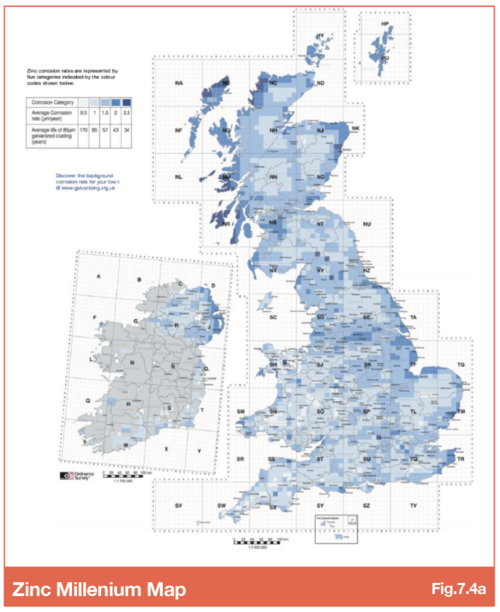

For exterior exposed structures, the geographical location (both country and region) will influence the corrosion category applicable, refer Fig.7.4a.

The Zinc Millenium Map (Fig.7.4a) indicating regional corrosion categories (Galvanisers Association, 2011).

Corrosivity Categories

C1 - Very low

Indoor - Heated spaces with low relative humidity and insignificant pollution, e.g. offices, schools museums.

Outdoor - Dry or cold zone, atmospheric environment with very low pollution and time of wetness, e.g. certain deserts, central arctic/Antarctica.

C2 - Low

Indoor - Unheated spaces with varying temperature and relative humidity. Low frequency of condensation and low pollution, e.g. storage, sports hall.

Outdoor - Temperate zone, atmospheric environments with low pollution (SO2 < 5μg/m3), e.g. rural areas, small towns. Dry or cold zone, atmospheric environment with short time of wetness, e.g. deserts, subarctic areas.

C3 - Medium

Indoor - Spaces with moderate frequency of condensation and moderate pollution from production process, e.g. food-processing plants, laundries, breweries, daries.

Outdoor - Temperate zone, atmospheric environment with medium pollution (SO2 : 5μg/m3 to 30μg/m3) or some effect of chlorides, e.g. urban areas, coastal areas with low deposition of chlorides. Subtropical and tropical one, atmospheric with low pollution.

C4 - High

Indoor - Spaces with high frequency of condensation and high pollution from production process, e.g. industrial processing plants, swimming pools.

Outdoor - Temperate zone, atmospheric environment with high pollution (SO2: 30μg/m3 to 90μg/m3) or substantial effect of chlorides, e.g. urban areas, industrial areas, coastal areas without spray of salt water or, exposure to strong effect of de-icing salts. Subtropical and tropical zone, atmospheric with medium pollution.

C5 - Very high

Indoor - Spaces with very high frequency of condensation and/or with high pollution from production process, e.g. mines, caverns for industrial purposes, unventilated sheds in subtropical ad tropical zones.

Outdoor - Temperate and subtropical zone, atmospheric environment with a very high pollution (SO2 : 90μg/m3 to 250μg/m3) and/or significant effect of chlorides, e.g. industrial areas, coastal areas, sheltered positions on coastline.

CX - Extreme

Indoor - Spaces with almost permanent condensation or extensive periods of exposure to extreme humidity effects and/or with high pollution from production process, e.g. unventilated sheds in humid tropical zones with penetration of outdoor pollution including airborne chlorides and corrosion-stimulating matter.

Outdoor - Subtropical and tropical zone (very high time of wetness), atmospheric environment with very high SO2 pollution (higher than 250μg/m3) including accompanying and production factors and/ or strong effect of chlorides, e.g. extreme industrial areas, coastal and offshore areas, occasional contact with salt spray.

Life to First Maintenance

The expected Life to First Maintenance is the estimated duration of effective protection of the steel by the metallic coating against perforation.

To determine the most accurate ‘Life to First Maintenance’, the environment in which the material will be located must be carefully assessed to determine which of these categories is applicable for the location in question.

Guidance values for Life to First Maintenance are show in Table 7.4a.

From Table 7.4a, it is apparent that identifying the corrosivity category for the design situation is key to obtaining an accurate life to first maintenance. The environment in which the material will be located must be carefully assessed to determine which of these categories is applicable for the location in question.

Table 7.4a Guidance of ‘Life to First Maintenance’ periods for coating options available for SMD products.

(Galvanizers Association, 2011)

The periods for standard coating are calculated from corrosion rates given by Corus Strip Products (2007).

Further guidance on Life to First Maintenance can be found in SCI P262, with Table 4.1 indicating predicted design life of up to 250 years for floors in warm frame applications, with no risk of water ingress or condensation and 100 years for suspended ground floors with over site membrane and low risk of water ingress; with some risk of condensation.

For further details on HD coating, refer to section 13.1.

The LTFM figures presented in the table above are similar to those documented by the galvanised steel suppliers for the different locations (shown below):

Internal:

Dry & Unpolluted: 20 – 50 years

(Typical for most common applications – offices, warehouses, hospitals, airports)

External:

Suburban & Rural: 5 – 10 years

Coastal: 2 – 5 years

Industrial and Urban: 2 – 5 years

More information available on our website regarding:-

Refer to SMD High Durability Coating for more information

Design Considerations when using steel deck construction for car parks

Durability of Steel Deck Composite Floors

Go to NEXT section