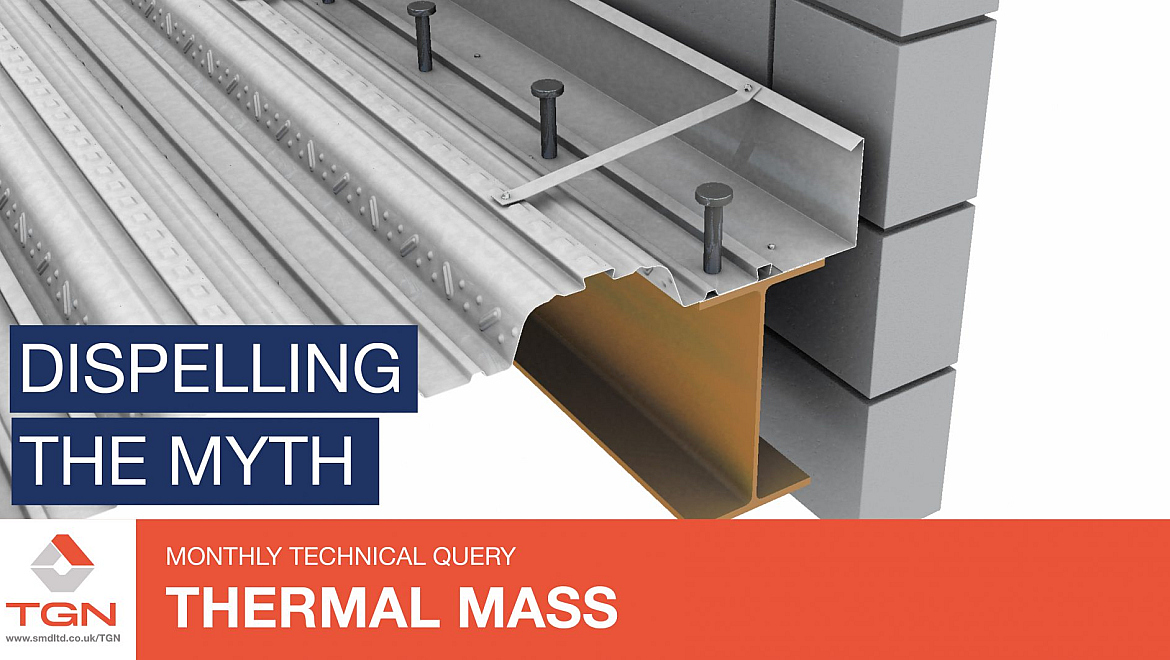

The fabric of a building can absorb and store heat generated by solar gain, equipment use and human activities; this is known as ‘Thermal Mass’. Used effectively in the heating and cooling design of a building, it can reduce the requirement for heating and air conditioning leading to savings in carbon and operational costs during the building lifecycle.

The fact that heavyweight concrete structures such as old churches and castles remain cool on a hot summers day has led to the common mis-conception that more concrete equals better thermal mass performance. The reason such buildings remain cool is due to the small number of windows (reducing solar gain) and light use reducing heat generated from occupants. So, nothing to do with the mass of the concrete structure at all!

Exposing the soffits of concrete floors in multi-storey non-domestic buildings provides the greatest potential for heat absorption.

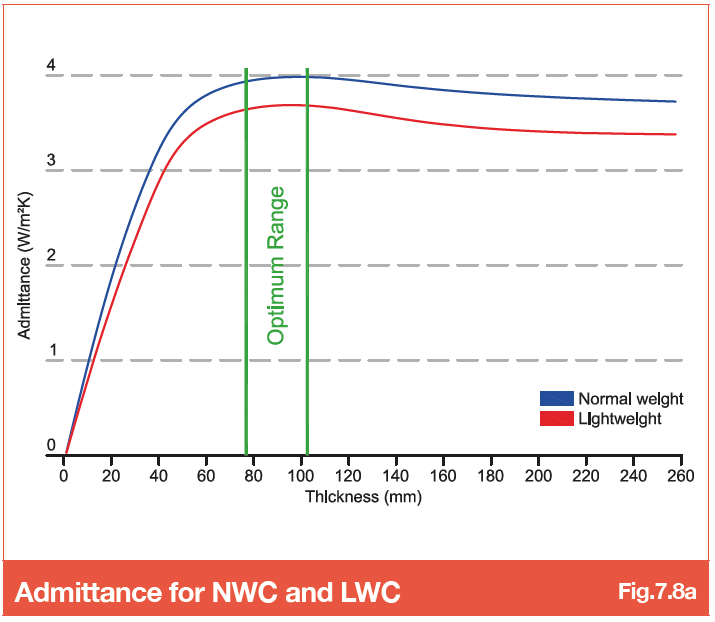

Following a study at Oxford Brookes University; BRE, The Concrete Centre and CIBS all acknowledge that 75-100mm provides the optimum thickness of concrete for mobilising thermal mass within a typical 24-hour cycle of heating and cooling, see Fig. 7.8a.

Typical composite slabs on R51+, TR60+ or TR80+ provide an effective concrete volume that meets this optimum thickness along with the following other benefits relating to thermal mass:

- Minimal cleaning is required to the deck after concrete pouring to achieve an acceptable exposed finish.

- Using an etch primer and site applied coating or SMD pre-coated floor deck products (PC) an enhanced aesthetic appearance can be achieved.

- SMD pre-coated (PC) products will also improve heat transfer and light reflection properties of the exposed soffit.

- As SMD floor decks are not flat, there is more than 1.3m² of soffit area per m² of ceiling area to mobilise thermal mass. This provides greater absorption capability than a flat concrete soffit.

- It is possible to embed water pipes in the slab to aid thermal performance. Embedding pipes within the composite slab provides heat transfer for heating and/or cooling of the building.

It is important to realise that utilising thermal mass may not be effective for all buildings. For example, the use of thermal mass in heavily compartmented buildings with restricted air flow or buildings in areas of noise pollution where ventilation may create disturbance would not be advisable. Where the use of thermal mass is proposed, a specialist audit of building energy use is recommended – more comprehensive information on this subject can be found here.

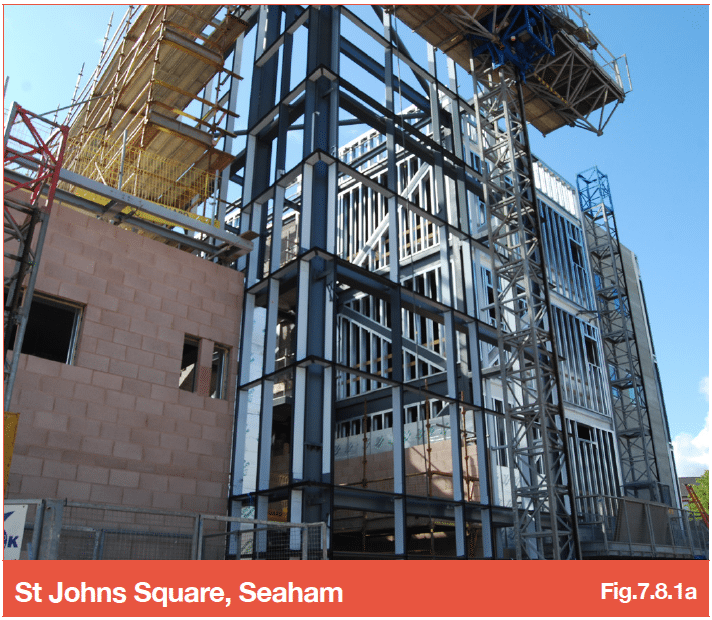

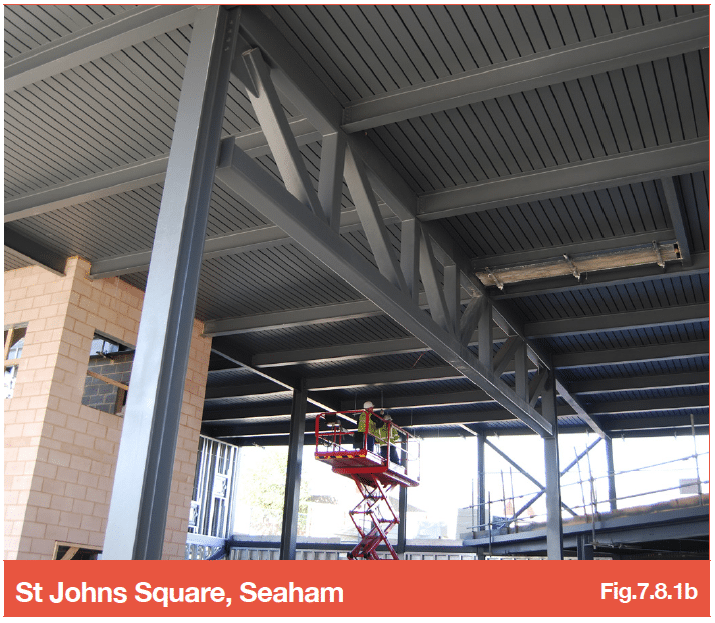

Pictures 7.8.1a and b show SMD contract at St John’s Square, Seaham for Hambleton Steel Ltd. The building housing a Public Library with Offices and a Café, involved the design, supply and installation of 2,700m² of SMD R51 with 130mm-160mm slab depth. Thermal mass of the composite slab was utilised by exposing the slab soffit and providing natural ventilation through stacks that penetrate the metal deck and floor slabs. The building on completion achieved a BREEAM ‘Very Good’ Rating.

TGN Online

For more information on this topic, see TGN Online Sections 7 for other Floor deck Considerations

Do you have a technical query?

Send your queries to our Technical Team

For Technical CPD’s, register your details for a presentation on this topic