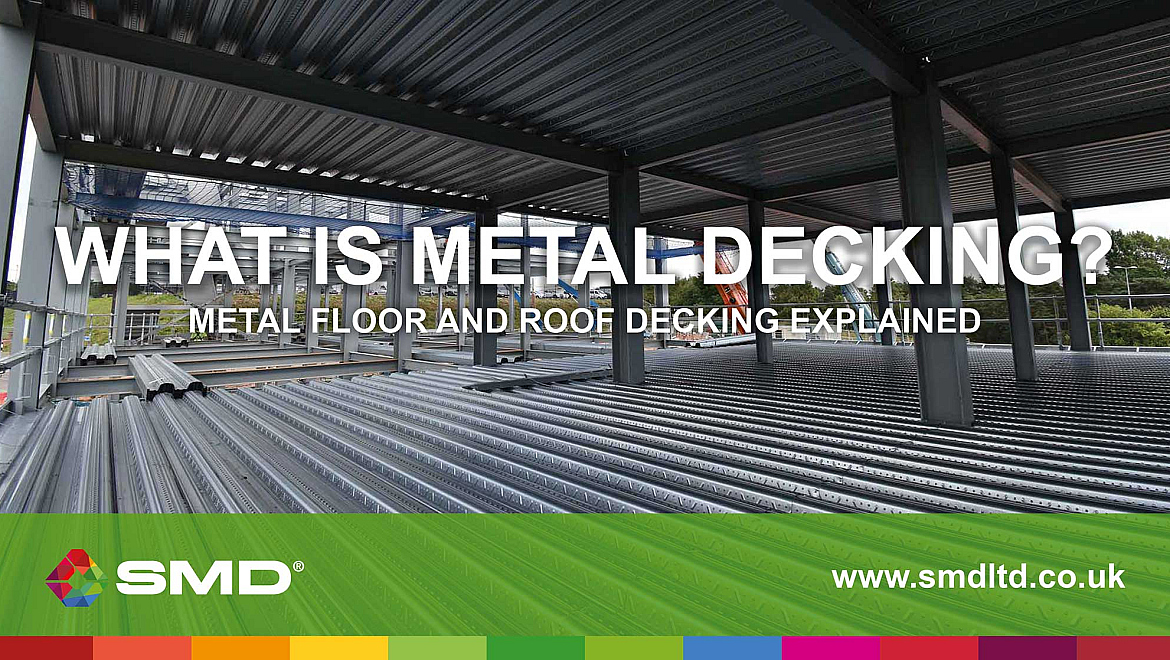

In the construction industry, the term ‘metal decking’ covers all forms of the profiled steel sheeting commonly used together with concrete and steelwork to create a composite floor system or as a structural element to support a built-up roof system. The decking typically comes in two different profiles, named for their specific shapes – dovetail (or re-entrant) and trapezoidal.

Metal decking in floor construction

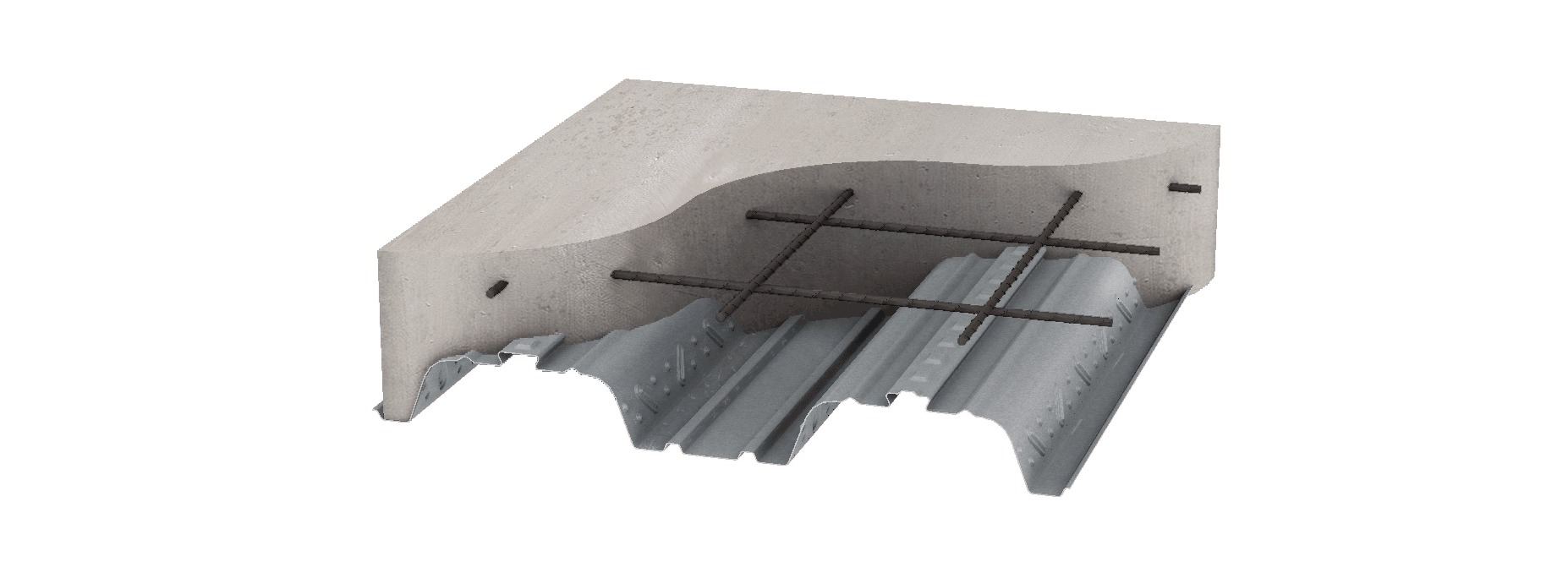

The combination of metal decking acting compositely with a concrete slab and a steel frame forms a lightweight, cost-effective floor construction that does not require the use of traditional formwork with props.

It’s a highly effective structural solution for multi-storey steel framed structures. And metal decking doesn’t necessarily have to be used as part of a composite floor system. On its own it can act purely as permanent formwork for non-composite, fully reinforced concrete slabs, again avoiding the use of traditional removable propping systems.

There are numerous other benefits of composite metal deck floor systems.

- Installation is rapid, even on complex steel layouts, reducing overall programme.

- The decking acts as a safe working platform and facilitates following trades immediately after installation.

- There’s an overall reduction in slab self-weight and therefore in loading on the steel frame and foundations, leading to a corresponding reduction in materials.

- The decking contributes to lateral restraint of the frame and provides tensile reinforcement of the slab.

- Site storage requirements and delivery movements for the decking are minimal.

- Slabs can achieve up to a 4 hour fire rating.

- The decking incorporates an integral ceiling and services fixing system.

Large-span Capacity

The trapezoidal profiles in particular result in a composite slab with superior span capability, reducing the number of intermediate steel supports required and increasing uninterrupted floor areas in the building as well as speed of construction. In this range, SMD offers TR60+ and TR80+ (60mm and 80mm high respectively) and the deeper TR220 (220mm high) can be specified for use in high strength ribbed reinforced concrete slabs, ideal for open-plan office spaces and car park construction where large column-free circulatory areas are required.

In floor construction, the metal deck sheets are spanned across and fixed to steel beams and the concrete slab is then cast on top. Once cured, the composite slab has superior strength while remaining relatively lightweight compared to traditional steel reinforced concrete or pre-cast floor solutions. Thru-deck welded shear studs along the beams not only act as anchorage for the deck – they also transfer horizontal shear forces between the steel beam and concrete slab. These studs are site-welded to the supporting beams through troughs in the decking.

The effectiveness of this form of construction is further increased when the metal deck acts in conjunction with the steel members to stabilise the entire building frame. The deck spanning perpendicular to the beams may be used as lateral restraint during construction and, through diaphragm action, to stabilise the entire structure by transferring wind loads back to the walls or columns. Transverse reinforcement of the concrete ‘flange’ over composite beams is usually provided by steel mesh and/or additional bars but in locations where the decking spans perpendicular to the beam centre line, the deck can also be considered as transverse reinforcement.

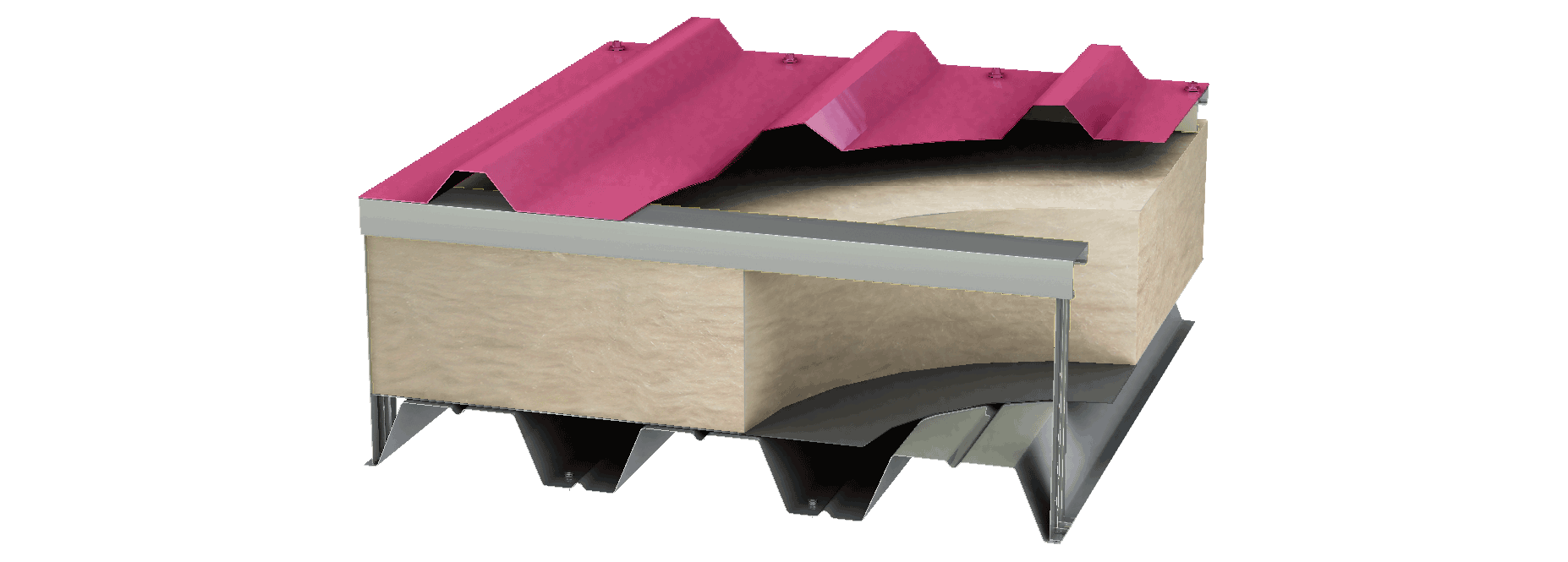

Metal decking in roof construction

Trapezoidal metal decking profiles can also be used to support various roofing systems, including single ply membrane or double-skin built-up systems, ‘green roofs’ and Standing Seam systems. It doesn’t form the actual roof finish but acts as a structural platform for the other materials. As with the floor deck profiles, it’s installed over and fixed to steel beams or purlins.

SMD’s SR range of roof deck profiles can be used as the steel liner for any of these built up roof systems. There are distinct advantages of this type of roofing system.

- Cost effectiveness and ease of installation.

- Efficient noise and heat insulation.

- High durability.

- Fewer intermediate supports due to long span capacity.

- A clean, uncluttered soffit and aesthetically appealing appearance where the soffit is exposed.

Like floor deck, structural roof deck can also act as a diaphragm to transfer wind loads from the perimeter elevations to internal vertical bracing or walls, therefore reducing the need for in-plane roof bracing and further enhancing the aesthetics by providing an uncluttered soffit.

The SR profiles are available in either galvanised or white liner finish, and for some products in specific colours to suit project specifications.

More Insight!

Complete the form below and we can send you a copy of our Corporate Magazine “Shaping the Skyline” which include many interesting articles on all aspects of metal decking activities. If you are currently working from home, we can send a Promotional pack to your home address this time but we won’t keep your details on file.