Difference between revisions of "12.10 - Surface flatness"

| Line 1: | Line 1: | ||

| − | Surface | + | Concrete Slab Surface Flatness is also referred to as Surface Regularity. Surface flatness must not be confused with surface level relative to a fixed datum. As recognised in BS 8204-2, MCRMA Technical Paper No.13 SCI Publication P300 and Concrete Society’s Technical Report No. 75, it is not possible to construct concrete floor slabs installed on metal decking to a tight surface flatness designation or a defined datum level due to both deck and steel frame deflections occurring during construction and when in service. It is vitally important for all concerned parties to understand such and due consideration should be given to this aspect by the Project Team when considering what effects this may have on supplementary trades / finishes i.e. subsequent levelling screeds may be necessary to attain such requirements. |

| + | |||

| + | Surface regularity is measured in accordance with methodology outlined under BS 8204-2 by placing a 2m long straightedge in direct contact with the concrete surface, resting under its own weight. Any deviations of the floor surface will then be measured from the underside of the straightedge, between points which are in contact with the floor surface by means of a slip gauge / graduated wedge (refer 12.10.a and b). | ||

| − | [[File:12.10a.jpg| | + | [[File:12.10a.jpg|500px|link=]] |

| − | + | Surface flatness designations (surface regularity) achievable with this type of construction are detailed in Table 12.10.a extracted from MCRMA Technical Paper No.13 SCI Publication P300. | |

| − | + | [[File:12.10a-table.jpg|500px|link=]] | |

| − | + | ||

| − | + | ||

| − | Where SMD are contracted to carry out the concrete works, surface flatness survey measurements will be taken at predetermined grid spacing’s to suit the slab area and steel configurations for the contract. | + | Where SMD are contracted to carry out the concrete works, surface flatness survey measurements will be taken at predetermined grid spacing’s to suit the slab area and steel configurations for the contract. |

| + | |||

| + | As specified in MCRMA Technical Paper No.13 SCI Publication P300 the straightedge must always be positioned parallel to the supporting beams, i.e. perpendicular to the deck span. | ||

| + | |||

| + | In areas receiving a skip/easy float surface finish, the positioning of the straightedge will be adjusted if necessary to avoid being situated over any localised ridging caused by this method of surface finishing. | ||

| + | |||

| + | The greatest deviation measured is then recorded in a table format to correspond with a drawing identifying the straightedge locations and positions. On completion of works, a formal copy of the surface regularity survey will be issued in accordance with the above as evidence of compliance. | ||

| + | |||

| + | [[File:12.10b.png|500px|link=]] | ||

| + | |||

'''Refer to BS 8204-2:2003 + A2:2011: Screeds, bases and in situ floorings. Concrete wearing surfaces. Code of practice for more information''' | '''Refer to BS 8204-2:2003 + A2:2011: Screeds, bases and in situ floorings. Concrete wearing surfaces. Code of practice for more information''' | ||

Revision as of 13:41, 20 April 2022

Concrete Slab Surface Flatness is also referred to as Surface Regularity. Surface flatness must not be confused with surface level relative to a fixed datum. As recognised in BS 8204-2, MCRMA Technical Paper No.13 SCI Publication P300 and Concrete Society’s Technical Report No. 75, it is not possible to construct concrete floor slabs installed on metal decking to a tight surface flatness designation or a defined datum level due to both deck and steel frame deflections occurring during construction and when in service. It is vitally important for all concerned parties to understand such and due consideration should be given to this aspect by the Project Team when considering what effects this may have on supplementary trades / finishes i.e. subsequent levelling screeds may be necessary to attain such requirements.

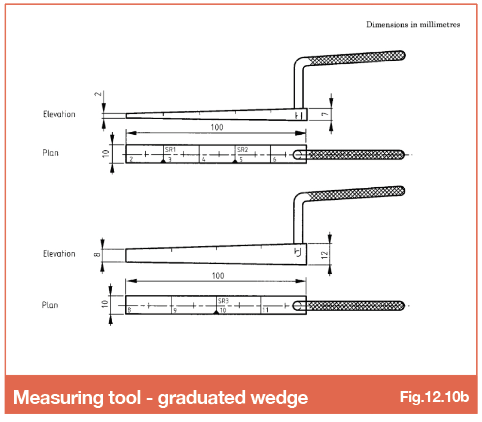

Surface regularity is measured in accordance with methodology outlined under BS 8204-2 by placing a 2m long straightedge in direct contact with the concrete surface, resting under its own weight. Any deviations of the floor surface will then be measured from the underside of the straightedge, between points which are in contact with the floor surface by means of a slip gauge / graduated wedge (refer 12.10.a and b).

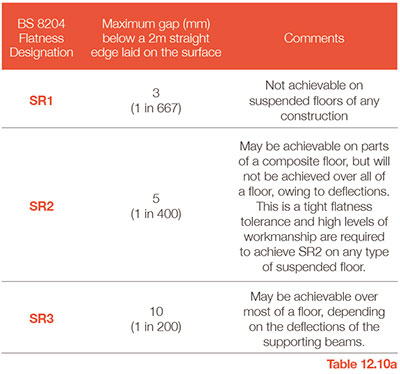

Surface flatness designations (surface regularity) achievable with this type of construction are detailed in Table 12.10.a extracted from MCRMA Technical Paper No.13 SCI Publication P300.

Where SMD are contracted to carry out the concrete works, surface flatness survey measurements will be taken at predetermined grid spacing’s to suit the slab area and steel configurations for the contract.

As specified in MCRMA Technical Paper No.13 SCI Publication P300 the straightedge must always be positioned parallel to the supporting beams, i.e. perpendicular to the deck span.

In areas receiving a skip/easy float surface finish, the positioning of the straightedge will be adjusted if necessary to avoid being situated over any localised ridging caused by this method of surface finishing.

The greatest deviation measured is then recorded in a table format to correspond with a drawing identifying the straightedge locations and positions. On completion of works, a formal copy of the surface regularity survey will be issued in accordance with the above as evidence of compliance.

Refer to BS 8204-2:2003 + A2:2011: Screeds, bases and in situ floorings. Concrete wearing surfaces. Code of practice for more information

Go to NEXT section