Difference between revisions of "12.5 - Construction joints"

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

With composite floor slabs, it is possible to achieve continuous concrete pours in excess of 1,000m2. | With composite floor slabs, it is possible to achieve continuous concrete pours in excess of 1,000m2. | ||

| Line 19: | Line 15: | ||

| − | + | Go to '''[[12.6 - Reinforcement drawings and bending schedules|NEXT]]''' section | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

Revision as of 09:58, 21 March 2017

With composite floor slabs, it is possible to achieve continuous concrete pours in excess of 1,000m2.

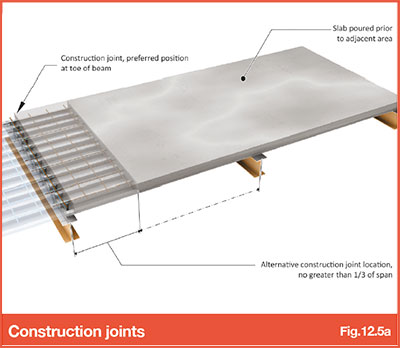

Where construction joints are required, these should always be formed as close as possible to the deck support at the butt joint in the deck sheets. The distance from the centre of the end support to the stop end should never exceed one-third of the span between the supports (Refer to Fig 12.5a).

Refer SMD Data Sheet SMD.DOD.178 - Construction Joint

Construction joints should be formed using either timber or one of the proprietary joint systems available for use on composite floor deck profiles. Where a day joint is required, adequate continuity reinforcement must be provided either by extending a sheet of mesh or additional bars through the joint location to provide slab continuity between pours.

Go to NEXT section