Difference between revisions of "13.6 - TAB-Deck™ – Fibre concrete"

| Line 4: | Line 4: | ||

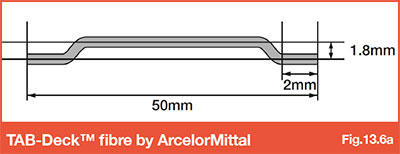

Developed in partnership with ArcelorMittal Sheffield Ltd, TAB-Deck ™ fibre reinforced concrete should be installed, cured and finished in exactly the same way as non-fibre reinforced concrete. The only fibre that has been extensively tested for use in TAB-Deck™ projects is Arcelor Mittal Sheffield Ltd HE 1/50 steel fibre (refer to Fig 13.6a) at a dosage of 30kg/m3. | Developed in partnership with ArcelorMittal Sheffield Ltd, TAB-Deck ™ fibre reinforced concrete should be installed, cured and finished in exactly the same way as non-fibre reinforced concrete. The only fibre that has been extensively tested for use in TAB-Deck™ projects is Arcelor Mittal Sheffield Ltd HE 1/50 steel fibre (refer to Fig 13.6a) at a dosage of 30kg/m3. | ||

| + | |||

[[File:13.6a.jpg|400px]] | [[File:13.6a.jpg|400px]] | ||

Revision as of 15:33, 25 January 2017

Back to main Contents page

Developed in partnership with ArcelorMittal Sheffield Ltd, TAB-Deck ™ fibre reinforced concrete should be installed, cured and finished in exactly the same way as non-fibre reinforced concrete. The only fibre that has been extensively tested for use in TAB-Deck™ projects is Arcelor Mittal Sheffield Ltd HE 1/50 steel fibre (refer to Fig 13.6a) at a dosage of 30kg/m3.

HE 1/50 Technical Specification:

- • Wire dimension = 1.0mm (+/- 0.04mm)

- • Fibre Length = 50mm (+/- 3mm)

- • Number of Fibres per kg = 3100 No

- • Total fibre length per 10kg = 1575m

- • Tensile strength of drawn wire = 1100 N/mm2

Rod wire C4D or C7D according to EN 10016-2

Concrete Design

The specific mix design will always depend on the local materials available but should follow these basic guidelines:

- • Cement – minimum 350kg/m3 of CEM I or CEM IIIA

- • Aggregates – maximum 20mm

- • Fines Content – minimum 450kg/m3 of smaller than 200μ including cementitious content

- • Water/Cement Ratio ≤ 0.50

- • Minimum Slump – 70mm (before the addition of steel fibres and super-plasticizer)

ArcelorMittal Sheffield Ltd can provide advice on individual mix designs and check suitability for specific projects.

Mixing

The best method for integrating the HE 1/50 steel fibre into the fresh concrete is by blast machines, available on request from ArcelorMittal Wire Solutions. This is a self-sufficient operation where the steel fibres are blown into the preloaded ready mix truck allowing easy homogenisation of the steel fibres into the concrete mix.

Alternatively, the steel fibres may be loaded via mobile conveyor belts or placed on the aggregate belt at the ready mix plant.

Finishing

Where a power float finish is specified when using steel fibres, consideration should be given by the Project Team for an application of a fibre suppressant dry shake topping which would significantly reduce the likelihood of exposed/protruding fibres becoming apparent in the final surface finish.

For further information and design guidance contact ArcelorMittal Sheffield Ltd or download SMD TAB-Deck™ design manual.

Other items within 13.0 - Product options:-