Difference between revisions of "4.5 - Bearings / Support"

| Line 1: | Line 1: | ||

=== 4.5.1 End bearing === | === 4.5.1 End bearing === | ||

| − | The minimum bearing requirements for the decking are 50mm on steelwork (this is increased to 60mm where sheets are to receive thru-deck welded shear studs, refer to Section '''[[6.0 - Design - Floor deck composite beam design]]''') and 70mm on masonry or concrete. | + | The minimum bearing requirements for the decking are 50mm on steelwork (this is increased to 60mm where sheets are to receive thru-deck welded shear studs, (refer to Section '''[[6.0 - Design - Floor deck composite beam design]]''') and 70mm on masonry or concrete. |

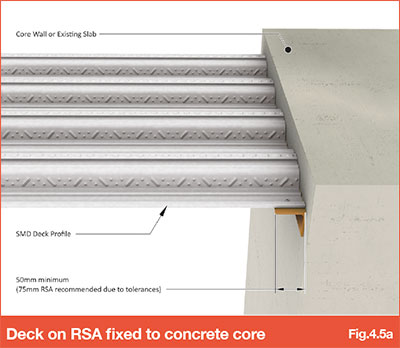

Where the deck is to butt up against a concrete core or similar, shelf angles are to be installed by others to provide adequate end bearing for the metal deck (refer to Fig 4.5a). When developing such a detail, consideration must be given to the height of any continuity reinforcement extending from the core to ensure it does not clash with the troughs of the deck profile. | Where the deck is to butt up against a concrete core or similar, shelf angles are to be installed by others to provide adequate end bearing for the metal deck (refer to Fig 4.5a). When developing such a detail, consideration must be given to the height of any continuity reinforcement extending from the core to ensure it does not clash with the troughs of the deck profile. | ||

Revision as of 09:19, 23 March 2022

4.5.1 End bearing

The minimum bearing requirements for the decking are 50mm on steelwork (this is increased to 60mm where sheets are to receive thru-deck welded shear studs, (refer to Section 6.0 - Design - Floor deck composite beam design) and 70mm on masonry or concrete.

Where the deck is to butt up against a concrete core or similar, shelf angles are to be installed by others to provide adequate end bearing for the metal deck (refer to Fig 4.5a). When developing such a detail, consideration must be given to the height of any continuity reinforcement extending from the core to ensure it does not clash with the troughs of the deck profile.

4.5.2 Shelf Angles or bottom flanges

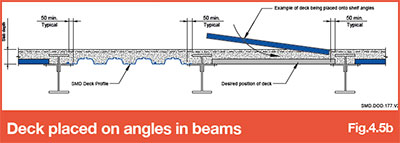

To reduce the structural zone it is sometimes necessary to install the decking onto angles fixed to the beam webs or bottom flanges. Where deck ends are supported on shelf angles or bottom flanges between beam webs, the shelf angle or bottom flanges must be designed to extend a minimum of 50mm beyond the toe of the beam top flange. This minimum dimension of 50mm is essential to enable the sheets to be physically positioned between toes of top flanges and provide access for a cartridge tool to be used to secure the decking into place (refer to Fig 4.5b).

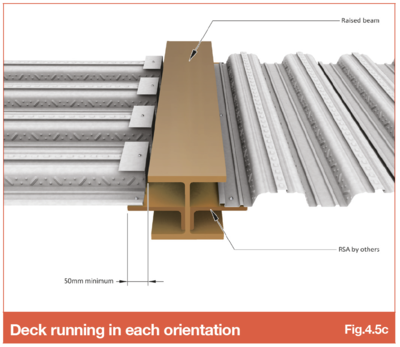

Where the deck spans parallel to the beam web a structural support angle is the recommended detail (refer to Fig 4.5c). It may be possible depending on spacing of secondary beams to utilise a 2.0mm gauge flashing to avoid the requirement for a structural angle, however this will impact on the slab capacity for high concentrated loads locally in the region of the non-structural flashing.

Refer to SMD Data sheet SMD.DOD.177 - Decking Bearing of Shelf Angle

Go to NEXT section