Difference between revisions of "8.13 - Fixing specification"

(Created page with "'''Back to main Contents page''' Body - First line Body - Last line ---- Other items within 8.0 - Design - Roof deck:- : 8.0 - Design - Roof deck : 8.1 -...") |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | The fixing options selected depend on the function they perform and supports to which they are being installed. | |

| + | '''Hot Rolled Steel Sections:''' | ||

| + | : • Shot-fired Hilti X-ENP-19 L15, these are not recommended for aluminium roof decks or when fixing in aggressive environments. If used in aggressive environments (i.e. category C4), additional fixing caps are likely to be required - contact Hilti UK for further information. | ||

| + | : • 5.5mm carbon steel drill screws, or stainless steel for more aggressive environments. | ||

| − | + | '''Cold-formed Steel Purlins:''' | |

| + | : • 5.5mm carbon steel drill screws, or stainless steel for more aggressive environments | ||

| + | |||

| + | '''Timber and/or Glulam Beams:''' | ||

| + | : • 6.5mm stainless steel screws | ||

| + | |||

| + | '''Side stitching of sheets and/or flashings:''' | ||

| + | : • Minimum 4.8mm carbon steel drill screws, or stainless steel for more aggressive environments | ||

| + | |||

| + | |||

| + | '''Aggressive Environments:''' The above fixing specifications should be enhanced for aggressive environments (ie. category C4) and when installing aluminium roof decks. For aluminium roof decks in aggressive environments (i.e. C4), stainless steel screws are recommended - contact fixing suppliers for suitable screw specification. | ||

| + | |||

| + | |||

| + | '''Note:''' All fixing types and centres (from Table 8.14a) will need specific checks for any uplift or diaphragm design required. This may result in a different fixing type or spacing to suit the design situation. For all fixing checks carried out, the performance data for the fixings should be tested in accordance with ECCS publication No. 124. | ||

| + | |||

| + | |||

| + | |||

| + | === 8.13.1 Fixing Centres and Locations === | ||

| + | |||

| + | Recommended minimum fixing centres for each profile are detailed in the table below. These may need to be increased in frequency and/or number where wind uplift load or diaphragm roof design is required – contact SMD Technical Team for further information. | ||

| + | |||

| + | |||

| + | [[File:8.13a-table.jpg|400px|link=]] | ||

| + | |||

| + | |||

| + | [[File:8.13a.jpg|400px|link=]] | ||

| + | |||

| + | |||

| + | The below restrictions on fixing position within the sheet are based on fixing types documented above, BS EN 1993-1-3 recommendations and Hilti literature in relation to cartridge fired pins. | ||

| + | |||

| + | |||

| + | '''Minimum edge/end distance and spacing''' | ||

| + | : • Fixing to end of sheet (A): 20mm minimum | ||

| + | : • Fixing to edge of support (B): 10mm minimum (based on steel flanges >7mm) | ||

| + | : • Distance between two fixings (C): 20mm minimum | ||

| + | : • Fixing to edge of sheet (D): 10mm minimum | ||

| + | |||

| + | |||

| + | [[File:8.13b.jpg|400px|link=]] | ||

| − | |||

| Line 11: | Line 51: | ||

| − | + | Go to '''[[8.14 - Flashing details|NEXT]]''' section | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

Latest revision as of 09:44, 16 December 2020

The fixing options selected depend on the function they perform and supports to which they are being installed.

Hot Rolled Steel Sections:

- • Shot-fired Hilti X-ENP-19 L15, these are not recommended for aluminium roof decks or when fixing in aggressive environments. If used in aggressive environments (i.e. category C4), additional fixing caps are likely to be required - contact Hilti UK for further information.

- • 5.5mm carbon steel drill screws, or stainless steel for more aggressive environments.

Cold-formed Steel Purlins:

- • 5.5mm carbon steel drill screws, or stainless steel for more aggressive environments

Timber and/or Glulam Beams:

- • 6.5mm stainless steel screws

Side stitching of sheets and/or flashings:

- • Minimum 4.8mm carbon steel drill screws, or stainless steel for more aggressive environments

Aggressive Environments: The above fixing specifications should be enhanced for aggressive environments (ie. category C4) and when installing aluminium roof decks. For aluminium roof decks in aggressive environments (i.e. C4), stainless steel screws are recommended - contact fixing suppliers for suitable screw specification.

Note: All fixing types and centres (from Table 8.14a) will need specific checks for any uplift or diaphragm design required. This may result in a different fixing type or spacing to suit the design situation. For all fixing checks carried out, the performance data for the fixings should be tested in accordance with ECCS publication No. 124.

8.13.1 Fixing Centres and Locations

Recommended minimum fixing centres for each profile are detailed in the table below. These may need to be increased in frequency and/or number where wind uplift load or diaphragm roof design is required – contact SMD Technical Team for further information.

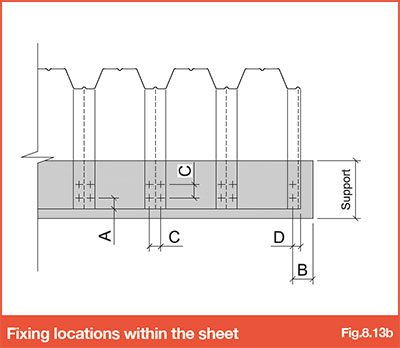

The below restrictions on fixing position within the sheet are based on fixing types documented above, BS EN 1993-1-3 recommendations and Hilti literature in relation to cartridge fired pins.

Minimum edge/end distance and spacing

- • Fixing to end of sheet (A): 20mm minimum

- • Fixing to edge of support (B): 10mm minimum (based on steel flanges >7mm)

- • Distance between two fixings (C): 20mm minimum

- • Fixing to edge of sheet (D): 10mm minimum

Go to NEXT section