12.9 - Surface finish

The concrete finish should be specified taking into consideration the proposed use of the floor slab and any surface finishes being applied. The slab finish may require additional surface preparation to facilitate the installation of some floor/roof finishes, advice should be sought from the finishes supplier. Where curing membranes are applied this must also be checked for compatibility with the subsequent applied finishes.

Surface finish is defined in BS EN 13670 Execution of concrete. This standard is adopted by NSCS 4th edition for concrete construction. For unformed finishes it is important not to ‘over-specify’ the quality of finish, particularly where it is covered up by following work; but whatever finish is specified, the concrete must be fully compacted.

The previous terminology was U1, U2 and U3 which generally correlates to Basic, Ordinary and Plain respectively. The default unformed finish assumed for all work is Basic.

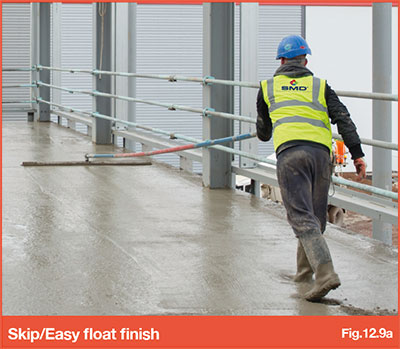

Basic (Skip/Easy Float)

Applicable for areas to receive a levelling or wearing screed. Normally a ‘trowel’ finish is applied to suspended upper floor concrete using a skip/easy float or similar type equipment.

It should be noted that this type of surface finish is likely to leave localised ridges, reinforcement ripple, surface laitance and a mottled effect in the final surface appearance, there is also a risk of reinforcement ripple. These areas may require some minor remedial attention prior to receiving subsequent floor finishes.

A 'basic' finish may be suitable to most areas but allowance should be given by the Project Team for the appropriate surface preparation (for the removal of float marks, localised ridges, weak layer) and possible use of primer necessary to resin fix pedestals or pass ‘pull off’ tests usually requested by the contractor responsible for raised access flooring or roofing finishes. A levelling screed or smoothing underlayment, in addition to appropriate surface preparation (for the removal of float marks, localised ridges and weak layer) and possible use of a primer, may also be required prior to the installation of thin sheet floorings.

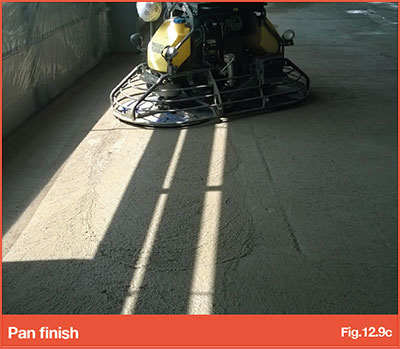

Ordinary (Powerfloating - Pan or Combi)

These can be provided (respectively defined as ‘Ordinary’ or ‘Plain’ in 4th edition of the National Structural Concrete Specification for building construction), although it must be specified in the context of the previous deflection section i.e. powerfloating will make the surface appear smoother and flatter, but not level to datum. Restrictions on working hours, particularly in built-up areas, may prevent the option of these types of finishes being provided.

Applicable for areas to receive flooring materials, types of false floor or other raised finish. It may not be suitable for thin vinyl flooring without grinding or an underlayment. This is a flat surface produced typically by power-floating but not by Basic (Skip/Easy Float) methods of surface finishing. A Pan finish will exhibit ridges (although not to the degree of Basic methods), provide a rough textured surface and will vary in consistency in its final appearance. A Combi finish will be free from ridges but float marks are to be expected.

These types of surface finishes may be acceptable for the application of finishes such as tiles or carpet. Surface preparation may be less extensive if an Ordinary finish is provided.

Plain (Powerfloating - Full Polish)

Applicable for areas without any other finish other than paint or surface coatings, and provides a uniform dense smooth surface typically produced by power-trowelling.

This may be suitable for directly trafficked surfaces. Due to its dense nature, a Plain finish may need abrading (typically, shot blast) to create a key to facilitate the application of subsequent finishes.

Go to NEXT section