4.7 - Cantilevers

Cantilevers or slab edge overhang / overhangs are constructed using deck, edge trim or a combination of both. In cantilever locations, the deck and/or edge trim acts as permanent formwork only and does not contribute to the tensile reinforcement for the cantilever. The slab cantilever in the final condition must be designed as fully reinforced considering the mesh reinforcement in the surface of the slab and taking no contribution from the deck and/or trim, to determine whether any additional reinforcement is required to support the final imposed loads. The design and detailing of this reinforcement is the responsibility of others.

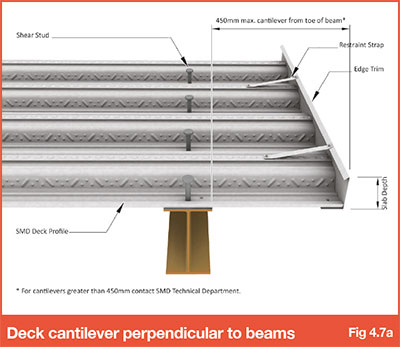

Where deck spans perpendicular to the edge beam in the direction of the cantilever (refer to Fig 4.7a), a maximum dimension of 450mm is recommended. This is a practical limitation for health and safety reasons, as typically the handrail is located on beam centre line and extending the cantilever further may result in unsafe practice beyond the handrail when stitching trim to the end of the sheet.

Refer to SMD Data sheet SMD.DOD.171 - Slab edge trim overhangs and cantilever deck

In locations where the above handrail issue does not apply it is possible to cantilever the deck up to 600mm depending on deck profile, gauge and slab depth. For cantilevers greater than 450mm contact SMD Technical Team as temporary propping may be required.

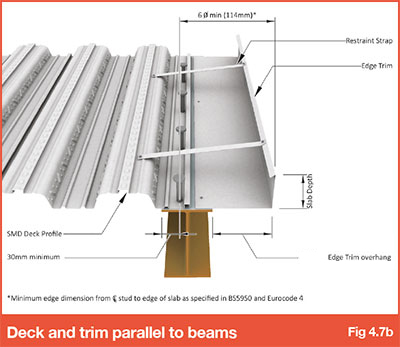

Deck spanning parallel to the edge beam

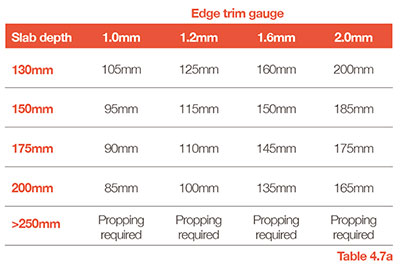

Cantilevers are achieved using edge trim (refer to Fig 4.7b). Decking must not be cantilevered at side locations without additional supports in place (refer to Fig 4.8c). The maximum achievable cantilever from edge of beam depends on the slab depth and edge trim gauge (refer to Table 4.7a for typical situations) up to a maximum of 200mm. For cantilevers or slab depths outside of this table contact SMD Technical Team.

Go to NEXT section