6.9 Pre-studded beams

On-site stud welding is the primary choice when installing shear studs to beams as the studs can be thru-deck welded to beams (once the deck is in-situ). Where it is not possible to site-weld shear studs, pre-studded beams are one solution to overcome this issue. A few reasons why site welding cannot take place can be due to:

- Installation required above public walkways or live public areas

- Installation required above swimming pools

- Installation required to internal, poorly vented areas

- Studs required to areas which are difficult to access

When designing pre-studded beams, there are a few rules to follow to ensure the studs are installed correctly and do not hinder the installation of the floor deck profiles.

Consideration

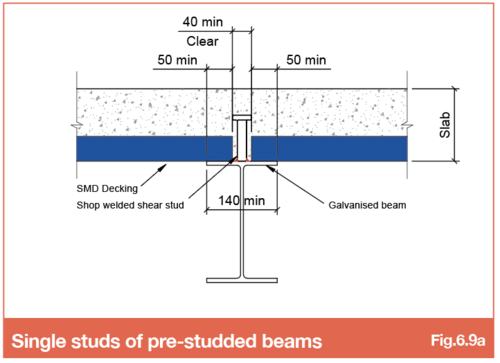

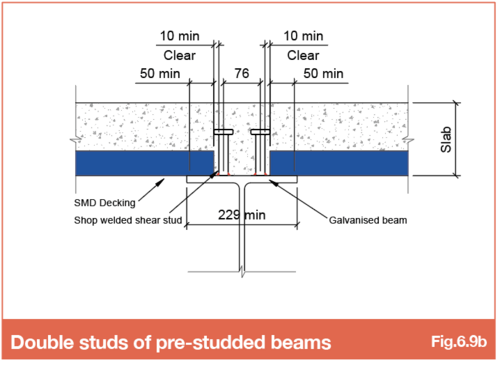

A key design and installation consideration to be aware of, all shear studs to be placed along the centre line of the beam allowing sufficient bearing for the floor deck to be fixed on the beam flange. It is suggested that a gap of 10mm maintained around the side of the stud to allow for the weld between the stud and the beam, as well as installation tolerances (giving slight movement for the deck sheets to be moved into place).

Tolerances and movement gaps

Due to this, it is suggested that the following beam sizes should be used based on the following stud requirements (using 19mm diameter studs):-

- 1 Row of studs = 140mm top flange

- 2 rows of studs (Pairs) = 229mm top flange

Spans

Deck sheets must be single span as they cannot be laid over or through mid-span pre-studded beams. Single span limitations will apply to each profile.

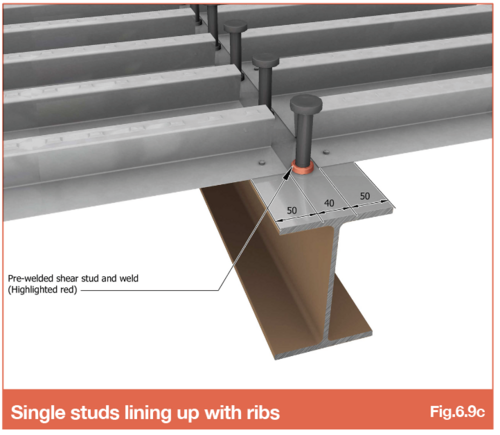

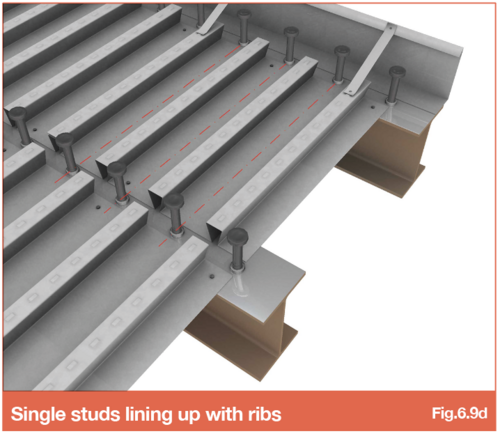

Lining up from beam to beam

The pattern of the shear studs from beam to beam should replicate the location of the deck troughs. To achieve their full composite action, studs must be positioned along the centre of the deck trough (refer Fig. 6.9c and 6.9d) allowing for sufficient concrete around the studs. It is suggested that SMD are consulted on the location of the shear studs from beam to beam as drawings and guidance can be provided to aid the design of this.

Back to Contents Page

Need Further Guidance?

Contact us on +44 (0)1202 718 898 or email our Technical Team