Difference between revisions of "4.6 - Fixings"

| Line 41: | Line 41: | ||

=== 4.6.4 Side stitching === | === 4.6.4 Side stitching === | ||

| − | At side-stitching of sheets and/or restraint strapping of edge trim, Hilti S-MD01Z 4.8 x 19, Fixfast DF3 HEX 4.8 x 20, or similar approved. | + | At side-stitching of sheets and/or restraint strapping of edge trim, 4.8mm diameter self-drilling metal screws with length suitable for fixing a total steel thickness of 3.5mm (Hilti S-MD01Z 4.8 x 19, Fixfast DF3 HEX 4.8 x 20, or similar approved). |

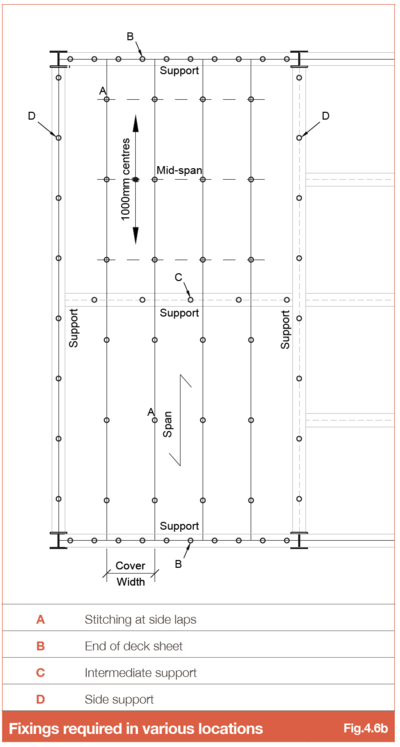

Side-stitching for all floor deck profiles is to be provided at maximum 1.0m centres from mid-span using self-tapping screws (refer mark A in Fig 4.6b). | Side-stitching for all floor deck profiles is to be provided at maximum 1.0m centres from mid-span using self-tapping screws (refer mark A in Fig 4.6b). | ||

Revision as of 15:38, 16 March 2022

Contents

4.6.1 Fixings to support

Recommended fixing types are as follows:

- • Where steel beams are to receive thru-deck welded shear studs, Hilti X-P14 G3 MX, Hilti X-U 15 (DAK) or similar approved.

Important Note: Beams to receive shear studs MUST have the top flanges left unpainted!

- • Where no shear studs are specified, Hilti X-ENP 19 or Spit SBR 14 shot-fired nails or similar approved should be used.

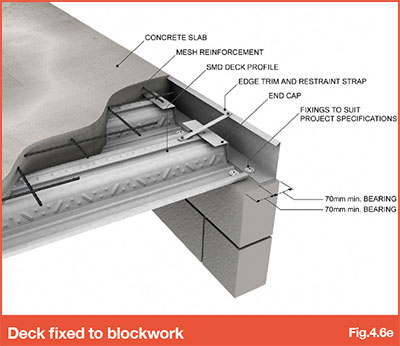

- • Fixings to masonry should be either Drill & Hammer Anchors (Spit P370 or P560, or similar approved) or shot-fired fixings (Hilti X-SW or Spit CR9 shot-fired nails or similar approved) refer to Fig 4.6e.

- • Fixings to concrete should be either similar to that for masonry (as mentioned above) or Hilti X-U nails or similar approved, length to suit base material and resistance required.

- • Fixings to Timber/Glulam Beams, or where shot-fired fixings are not permitted, should be self-drilling screws Fixfast DF12 5.5mm, Hilti S-MD55Z 5.5mm, or similar approved. Where screws are to be used on steel beam flanges thicker than 12mm, pre-drilling may be required, contact your fixing supplier for further guidance.

NOTE: When specifying fixings for a project, the fixing supplier should be consulted to ensure the length of fixing and specification (mentioned above) is appropriate for the support material and grade involved. The above guidance is based on fixing manufacturer’s literature which is subject to change without notice.

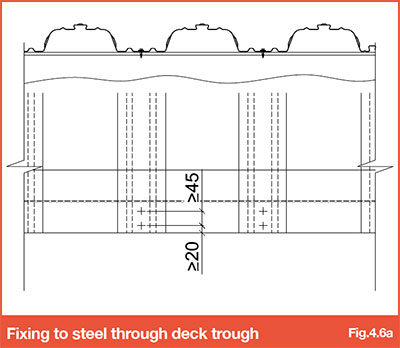

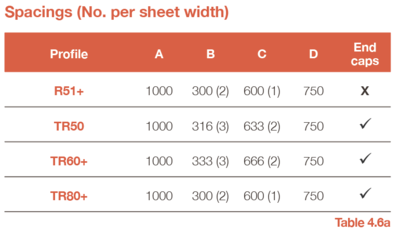

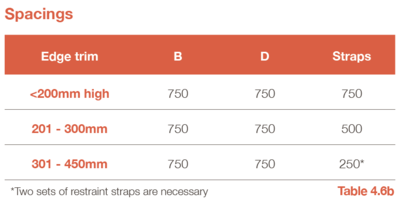

Decking must be fixed to supports at 300mm centres at each sheet end and at 600mm centres over intermediate supports, or closest multiples to suit trough centres, refer to Fig. 4.6b. Fixings should be located a minimum of 20mm from the end of the sheet and where more than one fixing per trough is specified, the spacing between fixings in the direction of the deck span is to be ≥ 45mm.

Where decking is required to provide lateral restraint and no thru-deck welded shear studs are specified, the fixing type should be checked by the engineer, refer to Section 4.4 - Lateral restraint and diaphragm action.

4.6.2 Wind Loading on temporary fixings

In exposed locations where beams that are to receive shear studs are left un-studded for a notable period of time, temporary fixings mentioned in 4.6.1 should be checked against wind loading. In these situations an enhanced fixing type or closer centres may be required. This subject is currently under investigation by BCSA, see Temporary Fixing of Metal Decking Interim Guidance or contact SMD Technical Team.

4.6.3 Additional fixings for MEWP frame erection

Where the steel contractor is using MEWP frames as part of the erection plan there may be a need to enhance the fixing type or centres. Where applicable, the steel contractor is to confirm the fixing type and centres required and identify the specific locations where MEWP frames are to be used.

4.6.4 Side stitching

At side-stitching of sheets and/or restraint strapping of edge trim, 4.8mm diameter self-drilling metal screws with length suitable for fixing a total steel thickness of 3.5mm (Hilti S-MD01Z 4.8 x 19, Fixfast DF3 HEX 4.8 x 20, or similar approved).

Side-stitching for all floor deck profiles is to be provided at maximum 1.0m centres from mid-span using self-tapping screws (refer mark A in Fig 4.6b).

Refer to BS EN 1993 or BS5950 for more information

Go to NEXT section