Difference between revisions of "5.4 - Moving concentrated loads"

m (uppdated table styling (borders)) |

(styling of HTML table and removing image of Table 5.4b) |

||

| Line 26: | Line 26: | ||

[[File:Table 5.4a.png|400px|link=]] | [[File:Table 5.4a.png|400px|link=]] | ||

| − | |||

| − | |||

{| class="wikitable" style="margin:auto" | {| class="wikitable" style="margin:auto" | ||

|+ Table 5.4b | |+ Table 5.4b | ||

|- | |- | ||

| − | !rowspan="2"| !! rowspan="2"|Profile !! rowspan="2"|Gauge (mm) !!colspan="5"|Slab depth (mm) | + | !rowspan="2" style="background-color:white;"| !! rowspan="2" style="background-color:#da5f44; color:white;"|Profile !! rowspan="2" style="background-color:#da5f44; color:white;"|Gauge (mm) !!colspan="5" style="background-color:#da5f44; color:white;"|Slab depth (mm) |

|- | |- | ||

| − | !130!!140!!150!!175!!200 | + | ! style="background-color:#da5f44; color:white;"|130!! style="background-color:#da5f44; color:white;"|140!! style="background-color:#da5f44; color:white;"|150!! style="background-color:#da5f44; color:white;"|175!! style="background-color:#da5f44; color:white;"|200 |

|- | |- | ||

| − | !style="border-bottom:solid 1px black;" rowspan="9"|HR12 MEWP | + | !style="border-bottom:solid 1px black; background-color:#da5f44; color:white;" rowspan="9"|HR12<br/>MEWP |

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|R51+ | |

| − | + | !0.9 | |

|2.20 | |2.20 | ||

|2.85 | |2.85 | ||

| Line 45: | Line 43: | ||

|2.50 | |2.50 | ||

|- | |- | ||

| − | + | !1.0 | |

|2.35 | |2.35 | ||

|3.10 | |3.10 | ||

| Line 52: | Line 50: | ||

|2.70 | |2.70 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"|2.40 | |style="border-bottom:solid 1px black;"|2.40 | ||

|style="border-bottom:solid 1px black;"|3.40 | |style="border-bottom:solid 1px black;"|3.40 | ||

| Line 59: | Line 57: | ||

|style="border-bottom:solid 1px black;"|3.00 | |style="border-bottom:solid 1px black;"|3.00 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|TR60+ | |

| − | + | !0.9 | |

| - | | - | ||

| - | | - | ||

| Line 67: | Line 65: | ||

|1.90 | |1.90 | ||

|- | |- | ||

| − | + | !1.0 | |

| - | | - | ||

| - | | - | ||

| Line 74: | Line 72: | ||

|2.10 | |2.10 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"| - | |style="border-bottom:solid 1px black;"| - | ||

|style="border-bottom:solid 1px black;"| - | |style="border-bottom:solid 1px black;"| - | ||

| Line 81: | Line 79: | ||

|style="border-bottom:solid 1px black;"|2.20 | |style="border-bottom:solid 1px black;"|2.20 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|TR80+ | |

| − | + | !0.9 | |

| - | | - | ||

| - | | - | ||

| Line 89: | Line 87: | ||

|1.50 | |1.50 | ||

|- | |- | ||

| − | + | !1.0 | |

| - | | - | ||

| - | | - | ||

| Line 96: | Line 94: | ||

|1.60 | |1.60 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"| - | |style="border-bottom:solid 1px black;"| - | ||

|style="border-bottom:solid 1px black;"| - | |style="border-bottom:solid 1px black;"| - | ||

| Line 103: | Line 101: | ||

|style="border-bottom:solid 1px black;"|1.50 | |style="border-bottom:solid 1px black;"|1.50 | ||

|- | |- | ||

| − | !style="border-bottom:solid 1px black;" rowspan="9"|Genie GS1930 | + | !style="border-bottom:solid 1px black; background-color:#da5f44; color:white;" rowspan="9"|Genie<br/>GS1930 |

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|R51+ | |

| − | + | !0.9 | |

|2.95 | |2.95 | ||

|2.85 | |2.85 | ||

| Line 112: | Line 110: | ||

|2.50 | |2.50 | ||

|- | |- | ||

| − | + | !1.0 | |

|3.20 | |3.20 | ||

|3.10 | |3.10 | ||

| Line 119: | Line 117: | ||

|2.70 | |2.70 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"|3.40 | |style="border-bottom:solid 1px black;"|3.40 | ||

|style="border-bottom:solid 1px black;"|3.40 | |style="border-bottom:solid 1px black;"|3.40 | ||

| Line 126: | Line 124: | ||

|style="border-bottom:solid 1px black;"|3.00 | |style="border-bottom:solid 1px black;"|3.00 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|TR60+ | |

| − | + | !0.9 | |

|1.20 | |1.20 | ||

|1.90 | |1.90 | ||

| Line 134: | Line 132: | ||

|2.75 | |2.75 | ||

|- | |- | ||

| − | + | !1.0 | |

|1.20 | |1.20 | ||

|1.90 | |1.90 | ||

| Line 141: | Line 139: | ||

|3.05 | |3.05 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"|1.20 | |style="border-bottom:solid 1px black;"|1.20 | ||

|style="border-bottom:solid 1px black;"|1.90 | |style="border-bottom:solid 1px black;"|1.90 | ||

| Line 148: | Line 146: | ||

|style="border-bottom:solid 1px black;"|3.55 | |style="border-bottom:solid 1px black;"|3.55 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|TR80+ | |

| − | + | !0.9 | |

| - | | - | ||

|1.35 | |1.35 | ||

| Line 156: | Line 154: | ||

|3.55 | |3.55 | ||

|- | |- | ||

| − | + | !1.0 | |

| - | | - | ||

|1.35 | |1.35 | ||

| Line 163: | Line 161: | ||

|3.90 | |3.90 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"| - | |style="border-bottom:solid 1px black;"| - | ||

|style="border-bottom:solid 1px black;"|1.35 | |style="border-bottom:solid 1px black;"|1.35 | ||

| Line 170: | Line 168: | ||

|style="border-bottom:solid 1px black;"|4.50 | |style="border-bottom:solid 1px black;"|4.50 | ||

|- | |- | ||

| − | !rowspan="9"|NANOSP (4.5m) | + | !rowspan="9" style="background-color:#da5f44; color:white;"|NANOSP<br/>(4.5m) |

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|R51+ | |

| − | + | !0.9 | |

|2.95 | |2.95 | ||

|2.85 | |2.85 | ||

| Line 179: | Line 177: | ||

|2.50 | |2.50 | ||

|- | |- | ||

| − | + | !1.0 | |

|3.20 | |3.20 | ||

|3.10 | |3.10 | ||

| Line 186: | Line 184: | ||

|2.70 | |2.70 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"|3.40 | |style="border-bottom:solid 1px black;"|3.40 | ||

|style="border-bottom:solid 1px black;"|3.40 | |style="border-bottom:solid 1px black;"|3.40 | ||

| Line 193: | Line 191: | ||

|style="border-bottom:solid 1px black;"|3.00 | |style="border-bottom:solid 1px black;"|3.00 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;" rowspan="3"|TR60+ | |

| − | + | !0.9 | |

|3.40 | |3.40 | ||

|3.30 | |3.30 | ||

| Line 201: | Line 199: | ||

|2.75 | |2.75 | ||

|- | |- | ||

| − | + | !1.0 | |

|3.75 | |3.75 | ||

|3.60 | |3.60 | ||

| Line 208: | Line 206: | ||

|3.05 | |3.05 | ||

|- | |- | ||

| − | + | !style="border-bottom:solid 1px black;"|1.2 | |

|style="border-bottom:solid 1px black;"|4.20 | |style="border-bottom:solid 1px black;"|4.20 | ||

|style="border-bottom:solid 1px black;"|4.05 | |style="border-bottom:solid 1px black;"|4.05 | ||

| Line 215: | Line 213: | ||

|style="border-bottom:solid 1px black;"|3.55 | |style="border-bottom:solid 1px black;"|3.55 | ||

|- | |- | ||

| − | + | !rowspan="3"|TR80+ | |

| − | + | !0.9 | |

| - | | - | ||

|4.25 | |4.25 | ||

| Line 223: | Line 221: | ||

|3.55 | |3.55 | ||

|- | |- | ||

| − | + | !1.0 | |

| - | | - | ||

|4.50 | |4.50 | ||

| Line 230: | Line 228: | ||

|3.90 | |3.90 | ||

|- | |- | ||

| − | + | !1.2 | |

| - | | - | ||

|5.10 | |5.10 | ||

| Line 239: | Line 237: | ||

The acceptable use of plant depends on the specific design criteria (i.e. spans, profile, slab depth etc). | The acceptable use of plant depends on the specific design criteria (i.e. spans, profile, slab depth etc). | ||

| + | |||

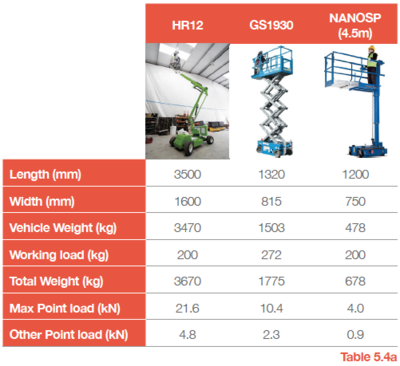

Table 5.4b covers the use of Plant on a cured slab during the construction stage, indicating acceptable spans for three pieces of plant classified as light (NANOSP), medium (GS1930) and Heavy (HR12) as defined in Table 5.4a. | Table 5.4b covers the use of Plant on a cured slab during the construction stage, indicating acceptable spans for three pieces of plant classified as light (NANOSP), medium (GS1930) and Heavy (HR12) as defined in Table 5.4a. | ||

Revision as of 15:00, 3 November 2023

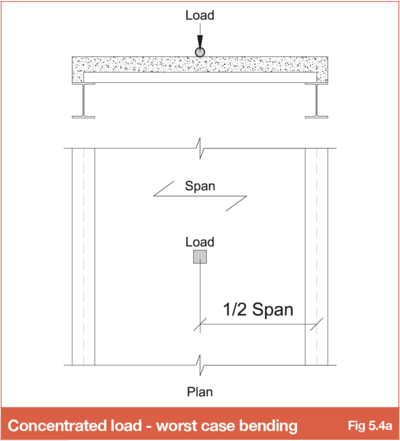

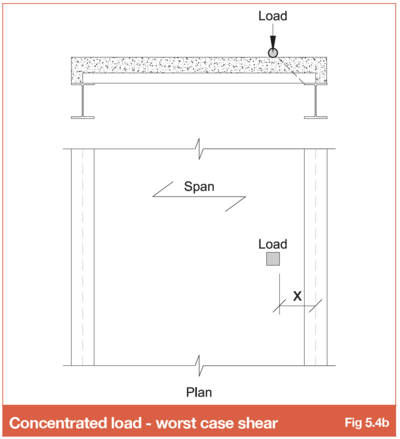

5.4.1 Critical design cases

For moving concentrated loads with typical design criteria, the common mode of failure is Horizontal Shear Failure at the deck/concrete interface, it is therefore essential to check the slab for:

1. Worst case bending at fire stage (with load positioned at mid-span)

2. Worst case shear at composite stage (with load positioned adjacent to the support)

When designing for concentrated loads, it is important to consider those that may be applied from plant during construction, as these may be more onerous than the final specified loadings for the building and will impact on the reinforcement required for the slab.

5.4.2 Typical plant that can be used on the slab during construction

There are many different makes and models of plant (MEWP, scissor lift or cherry picker) that can be used during the project construction phase, all of which have differing weights, wheel bases and worst case point loads.

| Profile | Gauge (mm) | Slab depth (mm) | |||||

|---|---|---|---|---|---|---|---|

| 130 | 140 | 150 | 175 | 200 | |||

| HR12 MEWP |

R51+ | 0.9 | 2.20 | 2.85 | 2.80 | 2.65 | 2.50 |

| 1.0 | 2.35 | 3.10 | 3.05 | 2.85 | 2.70 | ||

| 1.2 | 2.40 | 3.40 | 3.30 | 3.15 | 3.00 | ||

| TR60+ | 0.9 | - | - | - | - | 1.90 | |

| 1.0 | - | - | - | - | 2.10 | ||

| 1.2 | - | - | - | - | 2.20 | ||

| TR80+ | 0.9 | - | - | - | - | 1.50 | |

| 1.0 | - | - | - | - | 1.60 | ||

| 1.2 | - | - | - | - | 1.50 | ||

| Genie GS1930 |

R51+ | 0.9 | 2.95 | 2.85 | 2.80 | 2.65 | 2.50 |

| 1.0 | 3.20 | 3.10 | 3.05 | 2.85 | 2.70 | ||

| 1.2 | 3.40 | 3.40 | 3.30 | 3.15 | 3.00 | ||

| TR60+ | 0.9 | 1.20 | 1.90 | 2.95 | 2.95 | 2.75 | |

| 1.0 | 1.20 | 1.90 | 2.95 | 3.25 | 3.05 | ||

| 1.2 | 1.20 | 1.90 | 2.95 | 3.80 | 3.55 | ||

| TR80+ | 0.9 | - | 1.35 | 2.10 | 3.80 | 3.55 | |

| 1.0 | - | 1.35 | 2.10 | 4.15 | 3.90 | ||

| 1.2 | - | 1.35 | 2.10 | 4.65 | 4.50 | ||

| NANOSP (4.5m) |

R51+ | 0.9 | 2.95 | 2.85 | 2.80 | 2.65 | 2.50 |

| 1.0 | 3.20 | 3.10 | 3.05 | 2.85 | 2.70 | ||

| 1.2 | 3.40 | 3.40 | 3.30 | 3.15 | 3.00 | ||

| TR60+ | 0.9 | 3.40 | 3.30 | 3.20 | 2.95 | 2.75 | |

| 1.0 | 3.75 | 3.60 | 3.50 | 3.25 | 3.05 | ||

| 1.2 | 4.20 | 4.05 | 3.95 | 3.80 | 3.55 | ||

| TR80+ | 0.9 | - | 4.25 | 4.10 | 3.80 | 3.55 | |

| 1.0 | - | 4.50 | 4.40 | 4.15 | 3.90 | ||

| 1.2 | - | 5.10 | 4.95 | 4.65 | 4.50 | ||

The acceptable use of plant depends on the specific design criteria (i.e. spans, profile, slab depth etc).

Table 5.4b covers the use of Plant on a cured slab during the construction stage, indicating acceptable spans for three pieces of plant classified as light (NANOSP), medium (GS1930) and Heavy (HR12) as defined in Table 5.4a.

These tables are based on the following design assumptions:

- All spans designed as un-propped during construction

- This table considers Eurocode design only.

- Minimum mesh area greater than 0.2% of the cross sectional area of the slab (BS EN 1994-1-1: 9.8.1)

- 1.5kN/m2 construction load applied. No additional loads considered

- 1 hr fire rating

- Wheel sizes assumed as 100x100mm

- C25/30 Concrete Grade

- Max point load taken as 60% of Total Weight

Important Note: Where Plant is required during the life of the building, Table 4.5b does not apply, additional reinforcement may be required for serviceability due to the increased duration of wheel loads and higher imposed loads.

Refer to Concrete Society TR75: Composite Concrete Slabs on Steel Decking for more information

Refer to AD150: Composite Floors – Wheel Loads from Forklift Trucks for more information

Go to NEXT section