6.6 - Shear stud spacing

From TGN Online

Back to main Contents page

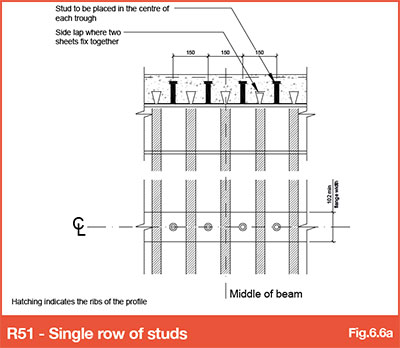

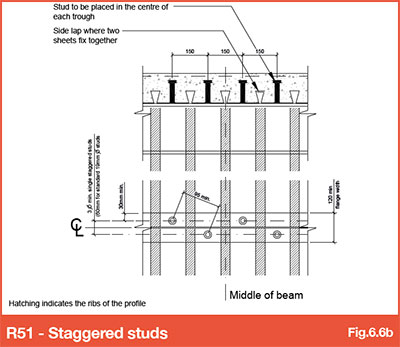

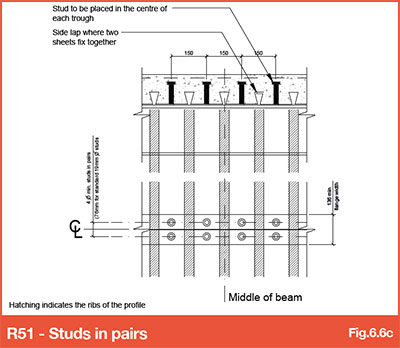

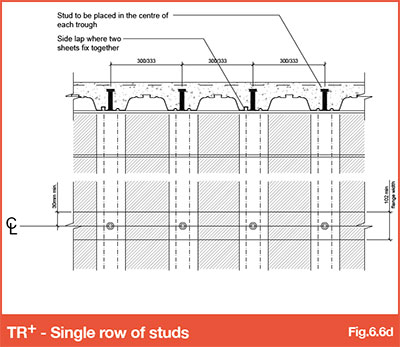

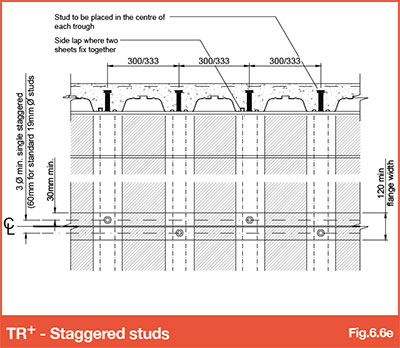

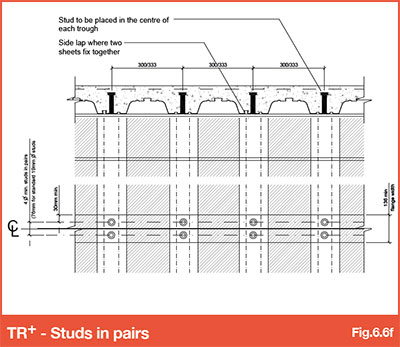

In accordance with BS EN 1994-1-1 or BS5950-3 Section 3.1:1990+A1 2010, the dimensions and configurations shown in Figs 6.6a to 6.6f must be followed to ensure the welded shear studs are effective to provide the documented stud resistance values.

Refer SMD Detail Sheet SMD.DOD.185 - R51 Single studs

Refer SMD Detail Sheet SMD.DOD.183 - R51 Staggered studs

Refer SMD Detail Sheet SMD.DOD.184 - R51 Studs in pairs

Refer SMD Detail Sheet SMD.DOD.182 - TR+ Single studs

Refer SMD Detail Sheet SMD.DOD.180 - TR+ Staggered studs

Refer SMD Detail Sheet SMD.DOD.181 - TR+ Studs in pairs

Other items within 6.0 - Design - Floor deck Composite beam design:-

- 6.0 - Design - Floor deck composite beam design

- 6.1 - Shear stud LAW (length after weld)

- 6.2 - Design rules for minimum degree of connection

- 6.3 - Shear stud reduction factors

- 6.4 - BS EN 1994-1-1 Reduction factors for SMD Products

- 6.5 - BS5950-3 Section 3.1 Reduction factors for SMD Products

- 6.6 - Shear stud spacing

- 6.7 -Transverse reinforcement for composite beams

- 6.8 - Alternative Shear Connectors