Difference between revisions of "7.4 - Durability"

| Line 13: | Line 13: | ||

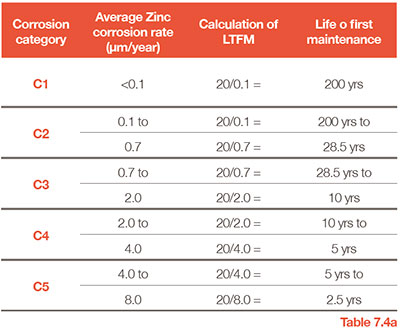

In summary, the above references conclude the LTFM for galvanised steel coil with a 20 μm coating as shown in Table 7.4a for the different corrosivity categories. | In summary, the above references conclude the LTFM for galvanised steel coil with a 20 μm coating as shown in Table 7.4a for the different corrosivity categories. | ||

| + | {| class="wikitable" style="text-align:right; width:400px; background-color:#fff;" id="Table_4.7a" | ||

| + | |+ style="caption-side:bottom; color:#e2503e; text-align:right;"|Table 7.4a | ||

| + | |- | ||

| + | !Corrosion Category!!Average Zinc corrosion rate (μm/year)!!Calculation of LFTM!!Life of first maintenance | ||

| + | |- | ||

| + | !rowspan="2"|C1 | ||

| + | |<0.1 | ||

| + | |20÷0.1= | ||

| + | |200 years | ||

| + | |- | ||

| + | !rowspan="2"|C2 | ||

| + | |0.1 to | ||

| + | |20÷0.1= | ||

| + | |200 years to | ||

| + | |0.7 | ||

| + | |20÷0.7= | ||

| + | |28.5 years | ||

| + | |- | ||

| + | !175mm | ||

| + | |90mm||110mm||145mm | ||

| + | |- | ||

| + | !C3 | ||

| + | |85mm||100mm||135mm | ||

| + | |- | ||

| + | !C4 | ||

| + | |85mm||100mm||135mm | ||

| + | |- | ||

| + | !C5 | ||

| + | |85mm||100mm||135mm | ||

| + | |} | ||

[[File:7.4a.jpg|400px]] | [[File:7.4a.jpg|400px]] | ||

Revision as of 12:33, 25 January 2017

Back to main Contents page

All SMD decks are manufactured from galvanised steel coil to BS EN 10346 with a standard 275g/m2 coating which equates to 0.02mm (20μm) per face. Although the galvanising provides a protective coating, it does weather, albeit at approximately one tenth of the rate of bare steel (depending upon the prevailing conditions).

Useful references on the life to first maintenance (LTFM) of galvanised steel coil include:

- • Galvanizers Association, “The Engineers and Architects Guide: Hot-dip Galvanizing”

- • Corus Strip Products UK, “Protected with strength - Solutions in Galvatite hot-dip galvanised steel”

- • The Steel Construction Institute, P262 - Durability of Light Steel Framing in Residential Building: Second Edition

- • SCI Advisory Desk Note 247: Use of Composite Construction in an Aggressive Environment,” New Steel Construction, April 2010.

In summary, the above references conclude the LTFM for galvanised steel coil with a 20 μm coating as shown in Table 7.4a for the different corrosivity categories.

| Corrosion Category | Average Zinc corrosion rate (μm/year) | Calculation of LFTM | Life of first maintenance | |||

|---|---|---|---|---|---|---|

| C1 | <0.1 | 20÷0.1= | 200 years | |||

| C2 | 0.1 to | 20÷0.1= | 200 years to | 0.7 | 20÷0.7= | 28.5 years |

| 175mm | 90mm | 110mm | 145mm | |||

| C3 | 85mm | 100mm | 135mm | |||

| C4 | 85mm | 100mm | 135mm | |||

| C5 | 85mm | 100mm | 135mm |

From Table 7.4a, it is apparent that identifying the corrosivity category for the design situation is key to obtaining an accurate life to first maintenance. The environment in which the material will be located must be carefully assessed to determine which of these categories is applicable for the location in question.

The LTFM figures presented in the table above are similar to those documented by the galvanised steel suppliers for the different locations (shown below):

- • Internal, Dry & Unpolluted = 20 – 50 years (Typical for most common applications – offices, warehouses, hospitals, airports)

- • Suburban & Rural = 5 – 10 years

- • Coastal = 2 – 5 years

- • Industrial and Urban = 2 – 5 years

Other items within 7.0 - Design - Floor deck, Considerations:-