7.8 - Thermal mass

Back to main Contents page

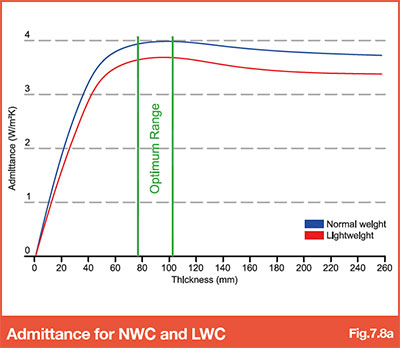

Following a study at Oxford Brookes University; BRE, The Concrete Centre and CIBS all acknowledge that approximately 100mm is the maximum thickness of concrete that can be mobilised within a typical 24-hour cycle of heating and cooling – refer graph below.

Composite slabs on R51, TR60+ or TR80+ in the region of 130mm-150mm thickness all provide an effective concrete volume that meets this 100mm optimum thickness.

Refer Steel Construction.info for further information

7.8.1 Case Study: St Johns Square, Seaham

Part of the SMD contract at St John’s Square, Seaham working for Hambleton Steel, utilises the thermal mass of the composite slab by exposing the slab soffit and providing natural ventilation through a series of stacks that penetrate the metal deck and floor slabs.

The building housing a Public Library with Offices and a Café, involved the design, supply and installation of 2,700m² of SMD R51 x 1.0mm gauge profile with slab thicknesses of 130mm and 160mm.

The building on completion achieved a BREEAM ‘Very Good’ Rating.

Refer www.steelconstruction.info/St_Johns_Square,_Seaham for further information

Other items within 7.0 - Design - Floor deck, Considerations:-