The word ‘design’ can mean different things to different people; useful industry references are used to discuss who is typically responsible for the various aspects in a steel deck composite slab.

As pointed out by the Steel Construction Institute (SCI) in AD482 ‘it is not uncommon to have different individuals responsible for particular aspects of the design, potentially separated by contractual arrangements’. However, within this context it is important to note that the project structural engineer is responsible, either directly or by co-ordination, for the overall design of the structure. At SMD, we often get asked to provide comment on design aspects outside of our area of responsibility. Although we are always happy to provide comment based on our experience, often these questions are about aspects of the design that we have little or no info.

SCI are in the process of revising their P300 publication titled: Composite Slabs and Beams using Steel Decking: Best Practice for Design and Construction, which has a section on the roles in design and construction. Part of this revision will include an update to roles and responsibilities to align it with the latest version of CDM regulations. In the list below some of the key design aspects within a composite beam/slab are covered with an indication of where the design responsibility typically sits and of how SMD can help at each stage of the design

Shear stud type and quantity

Shear stud type and quantity

Typically required for the steel-concrete composite beam design, the type and number is the responsibility of the steel frame designer for the project. This could be the consulting engineers on the project or, on design and build contracts, may be the steel frame contractor. SMD are happy to provide guidance on alternative stud types, configurations and layouts.

Product specification

Product specification

The deck profile, grade and thickness to be used is typically the responsibility of the steel frame designer (which could be consulting engineers or steel contractor as mentioned above). With projects typically utilising composite beams, this will have an impact on the profile selection as well as shear stud performance and spacings achievable. The SMD technical team is available to assist with recommendations for the optimum deck profile based on over 35 years’ experience of different building types, frame configurations and solving site problems.

Deck detailing

Deck detailing

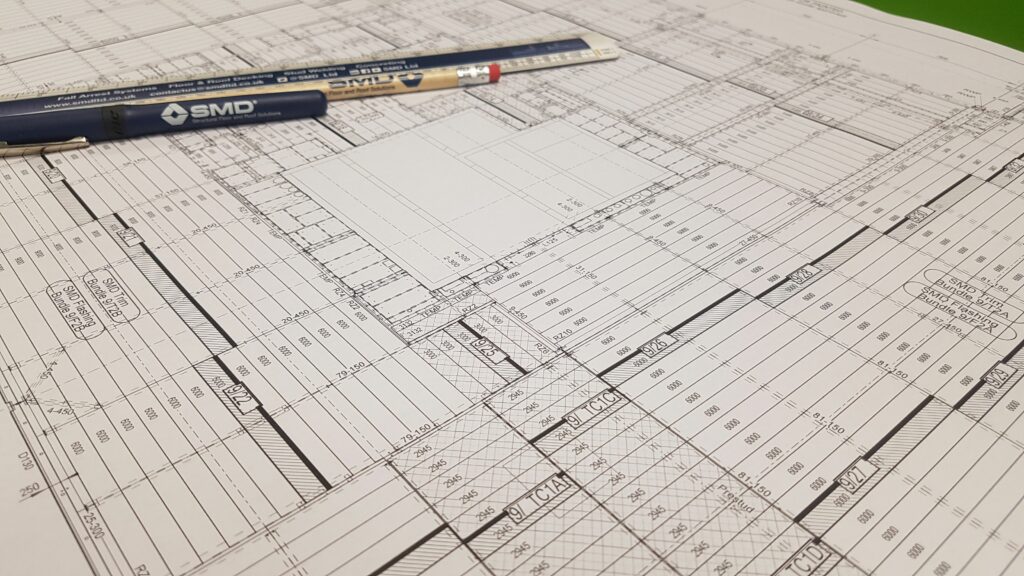

The detailing of deck sheets (numbers and lengths), closure flashings/edge trims, pack layout, etc is normally the responsibility of the decking contractor (who may also be the deck supplier as is the case at SMD). Where SMD is contracted to supply and install the decking for a project, we carry out a design review of information to identify any issues or deck requirements that may have a time critical impact on the frame contractor – this typically will involve a marked up drawing identifying any missing supports or areas where temporary propping is needed, thus enabling these to be addressed early without the need for additional cost for late remedials.

Slab design (reinforcement design and detailing)

Slab design (reinforcement design and detailing)

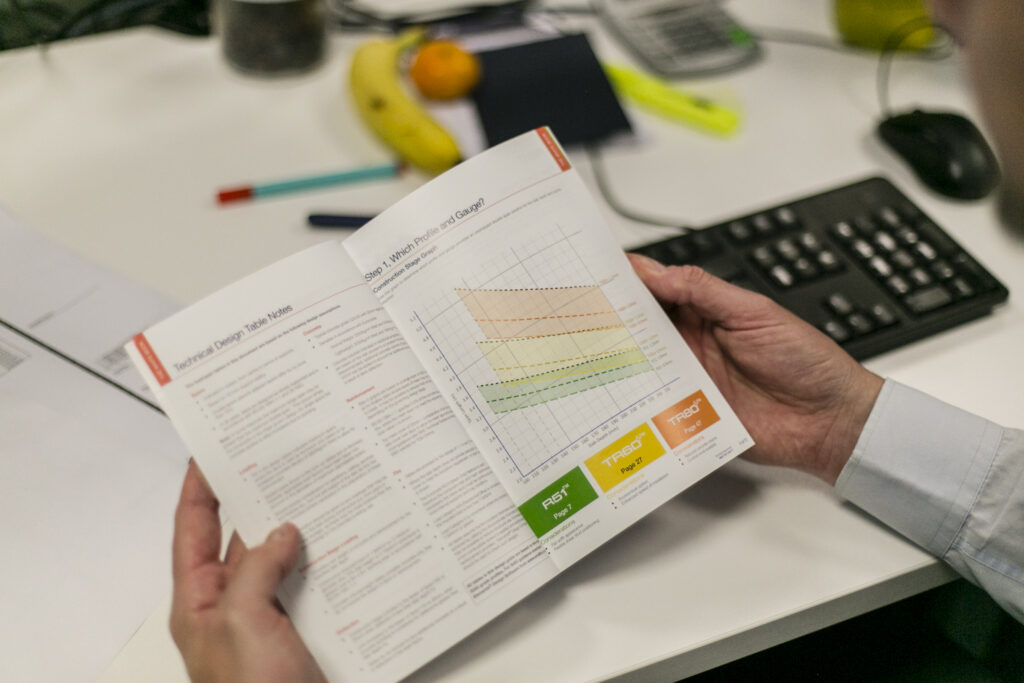

The design of the slab is the responsibility of the project structural engineer. Deck suppliers (like SMD) will provide design tools such as ‘The SMD White Book’ containing load span tables or ‘SMD Elements®’ design software, enabling the structural engineer to design the project with their chosen profile and identify the minimum reinforcement required. As the deck supplier, SMD are happy to support the designer with design calculations and guidance either via the Technical Team at concept stage or with our Contract Teams when working on a contract, but the responsibility remains that of the structural engineer as there are aspects of the slab that the deck supplier (or contractor) will not necessarily be aware of. These include; cantilevers with excessive loads that require additional reinforcement, voids that are being cut through or formed in the slab after the deck is in place, and any special or sensitive finishes that may require enhanced crack control resulting in an increase in reinforcement.

In addition to the reinforcement required for the design of the slab, there is likely to be reinforcement required for the composite beam design (i.e. U-bars or transverse bars over composite beams). To ensure both the slab and beam reinforcement is considered, detailed and included on a bar bending schedule it is recommended that this remain the responsibility of the project structural engineer. This will avoid the design risk (and potential additional time) that reinforcement may be missed where multiple parties are having to coordinate and then check details produced.

At SMD, we do offer three grades of slab design support from simple calculations (included on all contracts) to reinforcement markups or full reinforcement detailing and production of bar bending schedule. The two more comprehensive services come at a an additional cost and must be placed at point of order to ensure we can make the required resource available.

Hopefully the above gives some clarity to the aspects that can cause confusion during the life of a contract. Whilst the above gives a typical profile of the design roles and responsibilities, it is important to realise that the specific contract may state something different. Where this is the case it is critical to communicate this to all parties involved, to ensure they know what is being asked of them at tender stage so they can allow time, resource and money!

Engage with us early

Engage with us early

The SMD team is on hand at tender or pre-construction stage to aid with guidance and experience on any of the above mentioned stages and I would encourage customers and designers to engage with our teams early. Whether it be providing a quick piece of practical advice or pointing you to useful references (like the two below for specific reinforcement detailing challenges), we are here to help!