The above are the most typical options for use with SMD products. Other sizes are available.

Shear Studs and HVBs

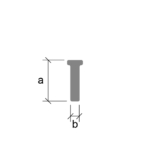

STUD95

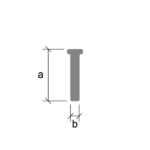

STUD120

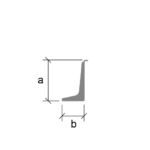

HVB95

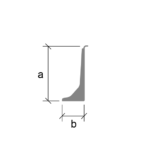

HVB125

Description

Headed shear studs can be directly welded, or through-deck welded, to the steel beam flange after the decking has been installed.

Benefits

Transmit the horizontal shear force between the concrete and beam connection and are commonly used in the design and construction of composite beams.

Benefits

• Unlike welded studs, HVBs can be installed to galvanised beams or in areas where a high fire risk exists.

• Fast and simple installation.

• No electrical power source required.

Specification

• Shear studs manufactured in accordance with BS EN ISO 13918:2008

• Yield Strength – 350N/mm² (minimum)

• Tensile Strength – 450N/mm² (minimum)

• Elongation – 15% (minimum)

Specification

• Yield Strength – 295-350N/mm²

• Zinc coating – ≥ 3 μm

Profile Properties

| Product | Product | Application | a | b | Fixing |

|---|---|---|---|---|---|

| STUD95 | Shear Stud | Welded | 95mm (LAW) | 19mm | Ferrules required |

| STUD120 | Shear Stud | Welded | 120mm (LAW) | 19mm | Ferrules required |

| HVB95 | Shear Connector | Mechanical | 95mm | 50mm | X-ENP-21 HVB |

| HVB125 | Shear Connector | Mechanical | 125mm | 51mm | X-ENP-21 HVB |

The above are the most typical options for use with SMD products. Other sizes are available.