Choosing the correct metal decking profile for your project, whether you’re in the market for floor or roof decking, can be complex and challenging. We’ve created some handy tips that might shed some light on why you should select one deck type over the other.

Things to consider prior to selecting a floor deck product

Before starting the deck selection process, the following factors should be considered:-

- Span limits

- Slab depth

- Slab loading

These are the obvious technical issues, but also in the mix are requirements for:-

- Aesthetic appearance of the slab soffit

- Building footprint shape (which may result in awkward steel beam configurations)

- Incorporation of services

- Cost

- Speed of installation

The most suitable decking solution will depend on which of these is your main priority.

Why choose metal floor deck at all?

Whichever profile best suits your needs, the greatest advantage in choosing metal floor deck construction is the avoidance of traditional floor slab temporary formwork, with its associated obstructive and time-consuming system of propping.

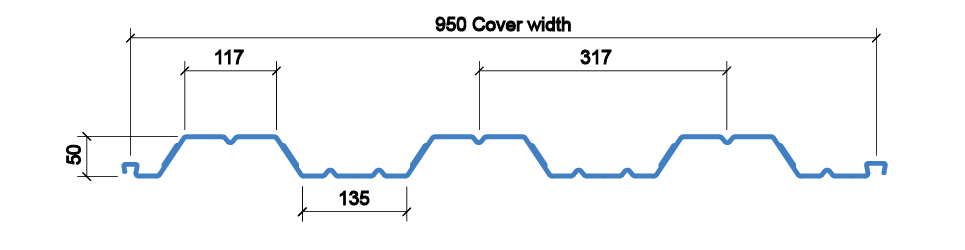

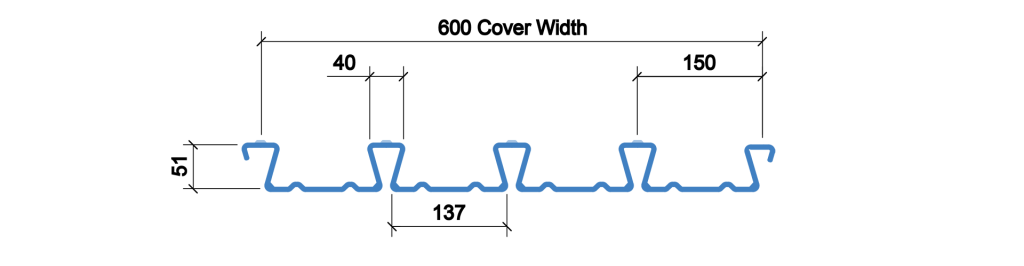

Floor decking typically comes in two different profiles – re-entrant (or dovetail) and trapezoidal (some manufacturers even offer a mixture of both in the same product). SMD supplies both of these profiles – R51+ being the re-entrant option and TR50, TR60+, TR80+ and TR220 being the trapezoidal options. A handy comparison of all these profiles is given at the back of our Services and Products brochure. The Product Selector starts on page 66 and includes a useful quick-reference table detailing and comparing the product properties.

So, how far can metal floor deck span?

We are often asked what is the maximum span for metal floor decking – in fact it’s one of the most common queries. The answer is straightforward enough as long as you know some basic information about the slab design.

In short, all our products have varying span performance. So to give you an idea, assuming the following criteria…..

- 150mm deep slab (probably the most common)

- 1.2mm gauge deck

- S350 grade material

- Double spanned deck condition

- Support widths being 127mm wide

- One-hour fire rating

then each of our products would be capable of achieving the following maximum double spans:-

- TR50 = 2.68m*

- R51+ = 3.56m

- TR60+ = 3.99m

- TR80+ = 5.01m

TR220 is a deep deck product with slab depths starting at 300mm, but with a single span limit of approximately 6m.

IMPORTANT – Spans are affected by all criteria including slab depth, loadings, fire rating etc. So should your project specification differ from the above, you can find your specific span limits in the SMD White Book.

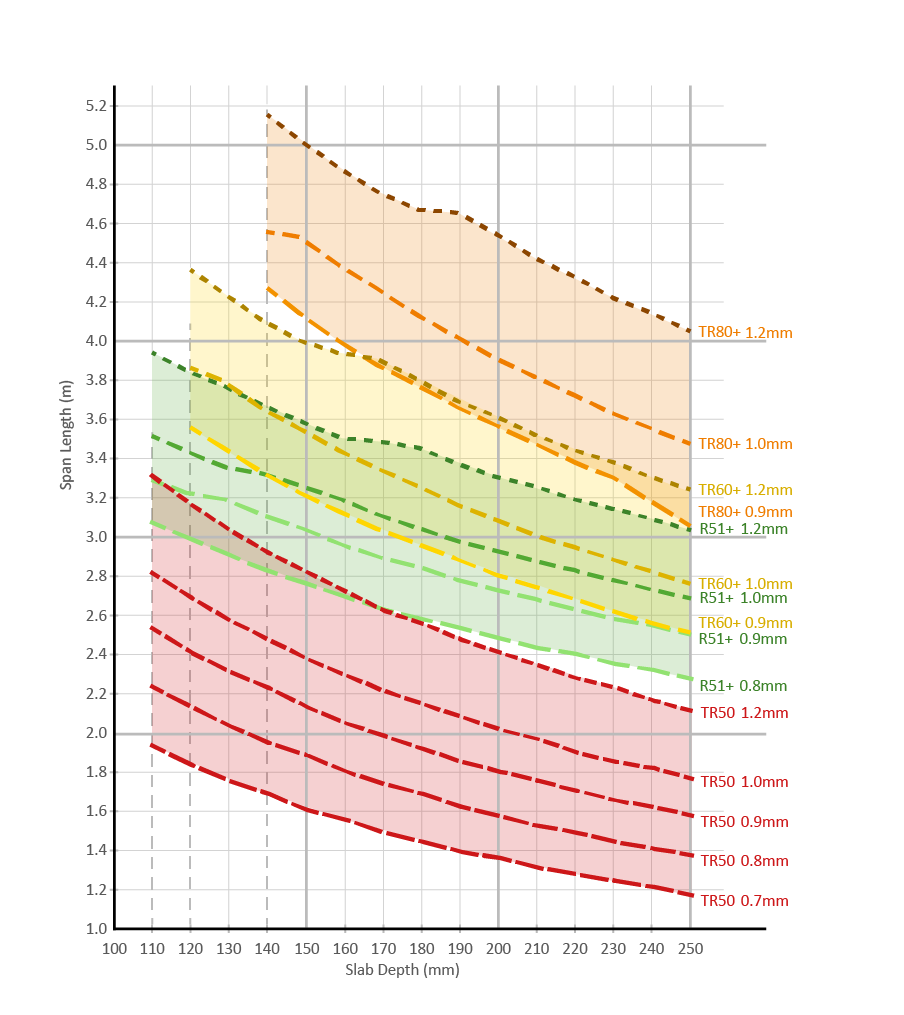

Above – Construction Stage Graph – Use this graph to determine which profile and gauge provides an unpropped double span solution for the slab depth and spans required (based on A393 mesh)

The White Book contains an easy visual reference to the parameters of each profile/gauge on page 8 (similar graph shown above). As the slab depth varies along the horizontal axis, so the range of each profile’s maximum span length alters on the vertical axis.

SMD floor deck options

TR50 – Rapidly installed permanent formwork

Our TR50 deck option is the most basic available. This profile should only be used as formwork for non-composite, fully reinforced concrete slabs, and the design of the slab reinforcement must not take into account the action of the metal decking. The large cover width allows for rapid installation.

R51+ – Thinner slabs and superior versatility

R51+ is undoubtedly the most versatile option for the situations involving complex steelwork layouts. This profile has a relatively large flat area within each trough, which allows for flexibility of shear stud positions when the deck is cut on, or runs across, raking beams. Fewer closing flashings are required, even on simple beam layouts, due to this feature of the profile.

From an architectural perspective, use of R51+ results a more aesthetically appealing flat soffit to the slabs. The minimal intrusion of the re-entrant rib into the concrete means that a relatively thin slab depth achieves the typical 1 hour fire rating and therefore both the structural zone and storey height can be reduced. This feature also results in superior airborne sound reduction from a thinner slab. The small ribs are typically sealed with tape or expandable foam rather than the steel end caps needed for the trapezoidal profiles.

Structurally, the R51+ profile shape provides the most effective shear stud performance of all composite decking profiles.

TR60+ and TR80+ – Increased spans, reductions on concrete and steel

The structural TR+ profiles are exceptionally resistant to compressive buckling, resulting in superior span capability. The lower volume of concrete required results in a reduced slab self-weight and therefore a reduced steel requirement.

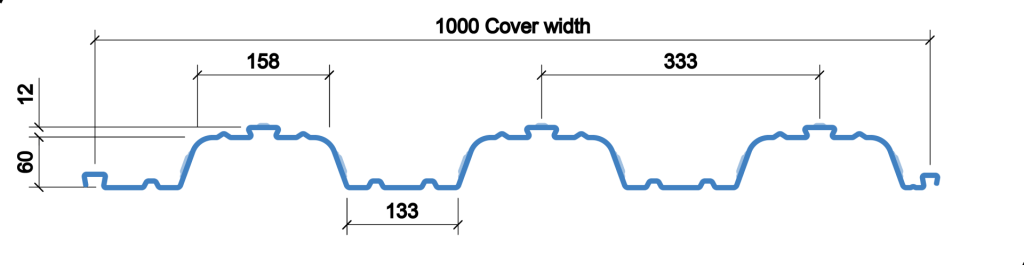

The TR60+ profile (above) enables un-propped spans in excess of 3.5m and is relatively quickly installed due to the 1m cover width.

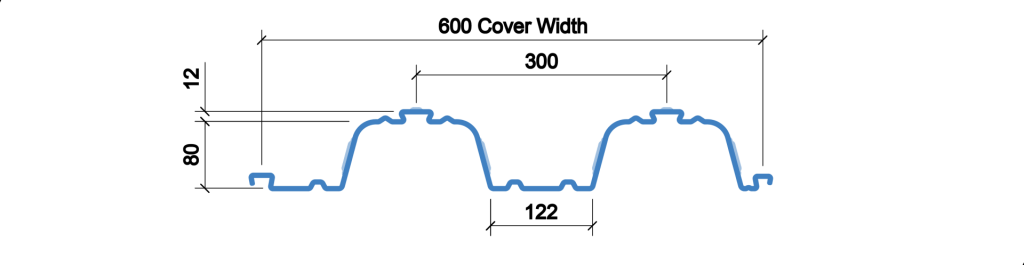

Use of the deeper TR80+ profile (above) gives engineers scope to reduce still further the number of secondary beams required and achieve further cost savings. This deck allows for long un-propped spans and correspondingly larger uninterrupted floor areas.

Trapezoidal profiles have significantly larger ribs than the re-entrant type and often beams that are parallel to the deck span and require shear studs are located directly under one of the ribs. In these cases, galvanised mild steel V-shaped or Z-shaped closing pieces, known as flashings, are required and are supplied as part of the decking package. At the perimeters and at internal voids, or on beams where a change of span direction occurs, the ends of the sheets are sealed with 0.7mm gauge galvanised end caps.

TR220 – Ultra long-span flooring solution

SMD’s TR220 can be used to form a high strength ribbed reinforced concrete slab, providing a slim floor construction with un-propped spans in excess of 6m. This type of deck profile is ideal for car park construction where large column-free parking and circulatory areas are required. The TR220 profile is usually fixed to the bottom flanges so that the slab depth is within the beam web depth to provide the reduced structural zone.

Product-specific options

Each profile is available in a variety of gauges and steel strengths that can be increased to accommodate more onerous loading conditions or span dimensions and thus avoid any mid-span propping. SMD offers a number of tools to assist designers with selecting the most suitable decking products in terms of type, gauge and strength.

‘The White Book’ has been developed as a quick reference tool for use during composite slab concept design. It will take the designer through a three-step process that will enable comparison of decking profiles with respect to slab thickness, load/span criteria, fire rating and the choice of either traditional mesh reinforcement or steel fibre-reinforced concrete.

Our Elements® Span Check app is a simple span look-up option which reflects all results shown in The White book, as a mobile app option available for both Android and Apple devices.

Some specific situations may not be covered by the information in The White Book, such as enhanced crack control or acoustic performance requirements and the SMD Technical Team will be able to provide guidance in these cases.

If you have isolated single span slabs, spans subjected to concentrated loads or simply need a full calculation report printout, more detailed design checks can be carried out using our Elements® Design Software.

Take a look at our YouTube video tutorials on use of the design software are also available.