Shear studs are typically specified at standard spacings. Where the beams are perpendicular to the deck, the profile geometry controls the tolerance in stud position. However, where beams are parallel the accuracy of stud spacings is down to the stud welder installing the studs. This article discusses why the tolerance on stud spacings on parallel beams is particularly important for composite edge beams.

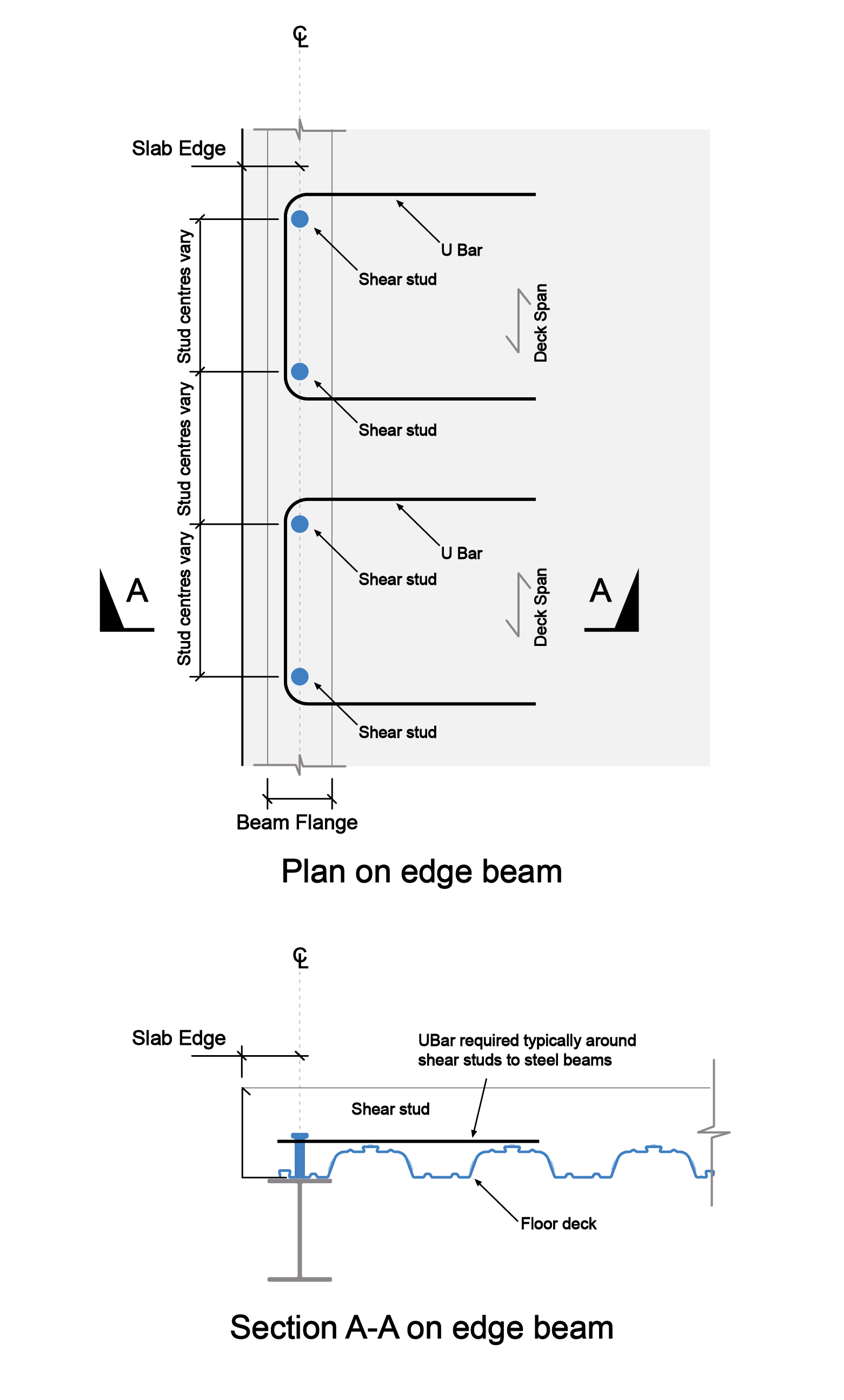

Shear stud requirements on beams running parallel to the deck span can be specified as either a number of studs or spacing. This results in the possibility of varying shear stud spacings on these beams with spacings typically varying from 150mm to 300mm and anything in between. For perimeter beams the common transverse reinforcement detail is to provide U bars around the studs in accordance with BS EN 1994-1-1, see extract from the engineers drawings on a recent project below.

The above detail, with a single U bar around each set of 2 studs along the beam, is not uncommon. This detail makes the tolerance on shear stud centres critical as the U bars will be detailed and scheduled on the bar bending schedule by the slab designer to suit the specified stud spacing. When preparing the bar bending schedules, it is important that the designer considers a tolerance within the bent U bar to ensure that practically the bars will fit around the 2 studs when the reinforcement is being fixed at site. To our knowledge there is no documented tolerance for on-site stud welding, however we would suggest as a minimum +/-10mm on each stud position be considered giving a tolerance in the U bar of at least 20mm.

One way to totally avoid any issues with stud spacing tolerance on U bars is to detail a single U bar around each stud. Whilst this reduces potential for issues at site, it comes with additional cost and is likely to take longer to install due to the increased number of bars.

Early engagement between SMD, the customer and structural engineer ensures issues such as that mentioned above are discussed early avoiding any unforeseen site issues and, in turn, providing programme certainty and cost control.