You may be aware of our TR80+ floor deck profile, an evolution of one of our original decking profiles, but did you know it’s available with crushed ends?

The light gauge steel framing sector.

Over recent years, we’ve seen the light gauge framing sector becoming more popular as this type of construction has evolved its purpose into higher rise buildings and is now a common form of construction used for hotels, residential and student accommodation to name a few. Our long span TR80+ floor deck profile provides a perfect choice for the contractors and method of installation used in this sector, and the crushed ends option available allows our clients to benefit from this optimum solution.

Find out more by downloading our TR80+ profile data sheet.

What are crushed ends?

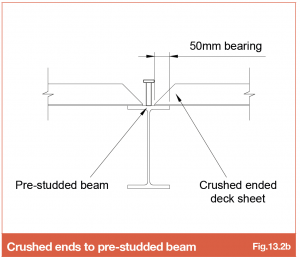

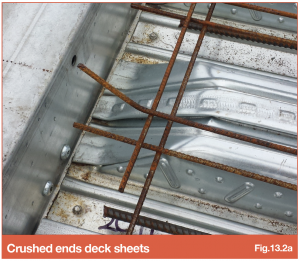

Crushed ends are the result of the process of closing the ends of the steel sheet deck by compressing the rib to create a slope at the end of the decking and forming a trapezoidal shape with a flat ‘toe’ at either end of the panel shown in the diagram below. This closing and shaping has a number of benefits both during installation and for client’s job specification too. As with all product options this is not suitable for some situations due to implications on sheet bundling and layout configurations. However, it’s worth finding out if your programme could benefit from crushed ends as they could work out to be a more cost-effective and more aesthetically-pleasing solution.

What are the benefits of crushed ends?

This type of decking is popular in light gauge frame construction or areas where the underside of the deck may be visible as there are plenty of benefits, both in cost and installation if the building design allows. For most, the main positive is that it reduces the installation times in single span situations as it means that no end caps need to be fitted – so you’ll save on labour costs.

When it comes to the concrete stage, crushed ends have further benefits still. Not only do they improve the reduction of grout loss at the ends of the deck sheets, but can also avoid the need for acoustic or fire profile fillers too (when used in combination with paint protection hot rolled steel beams as shown in fig.13.2b).